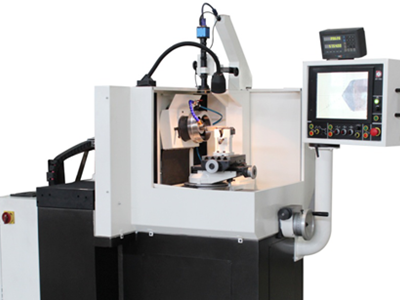

150M PCD Tool Grinding Machine

2020-02-11 12:31:35

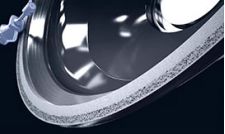

150M is designed for the economical manufacturing and regrinding of cutting tools made from PCD, PCBN, CVD, tungsten, carbide and other materials. It can grind angles and radii on standard and special turning and milling inserts, boring tools, grooving tools and many types of special turning tools.

I. Features:

1. Mechanical Structure: The base of machine is made of solid casting with high quality. It can meet grinding any requirements of hard material.

2. Grinding Spindle: With high precision and variable frequency, the spindle power is 3Kw, max speed is 3000r/min. The inner of spindle is cooled by recycling water. The radial run-out is 0.002mm and axial run-out is 0.003mm.

3. The feed slider is driven by pressure air, ensuring high production efficiency and good finish on cutting edges.

4. Wheel Oscillation: The grinding wheel oscillation is controlled by PLC program and move very smoothly. Oscillation length, position and frequency are adjustable on the panel;

5. CCD Measurement: Tool CCD image can be displayed, observed and measured on line with help of hairline.

6. Declination Lock: The grinding spindle declines along the circular guide smoothly and radial lock can be made, greatly enhancing the rigidity of the equipment. After declination, the center line of the grinding wheel keeps the same height due to special mechanical design,so coarse and fine grinding can be made without declination adjustment.

II. Technical Breakthrough

1. No vertical axis: vertical shaft lifting is not necessary because of height adjusting fixture on the workbench, greatly enhances the stability and rigid of the machine.

2. Tool automatic rotation: Once input the angle, rotation speed and hold time on the LCD control panel, the tool can rotate automatically to form radius and two straight cutting edges. If you hope to control the process totally, a switch button press can make it a total manual machine like bt-150. The machine only needs one hand to operate. The keen attention controls the most critical factor on the tool, the efficiency, the finish and the tolerance.

III. Main Technical Parameters

|

Spindle and Grinding Wheel

|

||

|

Diameter of Grinding wheel |

150mm |

|

|

Direct Drive Spindle with Water Cooling |

3KW |

|

|

RPM of Grinding Spindle |

0~3,000RPM |

|

|

Changeable Clearance Angle |

-5°~25° |

|

|

Grinding wheel center hole |

40mm |

|

|

Spindle Center Height |

150mm |

|

|

Grinding Wheel Oscillation System(X Axis) |

||

|

PLC Numerical Controlled Oscillation and Control on the Panel |

||

|

Max. Oscillation Range |

30mm |

|

|

Max. Oscillation Frequency |

60times/minute |

|

|

CCD Monitoring System |

||

|

Max Magnification of Optical Microscope |

4 times |

|

|

Magnification of CCD Measuring System

|

100times |

|

19Industrial Displayer |

19“ |

|

CCD Image Resolution |

1280*1024 |

|

Feed and Rotation System |

|

|

Compressor of Air Braking on Rotation Axis |

6bar |

|

Tool rotation (B axis) controlled by PLC. Can be switched to manual mode. |

LCD input |

|

Horizontal Transverse (Y Axis) Driven by Air |

70mm |

|

Linear Encoder Resolution (X Axis and Y Axis) |

0.001mm |

|

Power Supply and Dimensions |

|

|

Coolant Tank with Filter Paper |

about70L |

|

Electrical Supply |

12Kw |

|

Voltage Requested |

380V/Three phase /50Hz |

|

Overall Dimensions L╳W╳H |

1700╳1150╳1970mm |

|

Weight With Coolant Tank |

2000Kg |

<< Prev Article:Toughening of ceramic materials(Whisker ceramic inserts)

<< Next Article:Grinding characteristics of PCD and sharpening technology of PCD tools

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220