In order to meet the increasing requirements of users,the grinding wheel of moresuperhard is constantly updated and iterated.With the improvement of customers' requirements for cutting tools, the application of peripheral grinding wheels for indexable CNC inserts is becoming more and more extensive. Moresuperhard Co., Ltd. has developed a new formula specifically for this application to meet customer requirements. Today, please take a look at the specific usage data of this periphera diamond grinding wheel.

Resin peripheral grinding wheel first experimental parameters

|

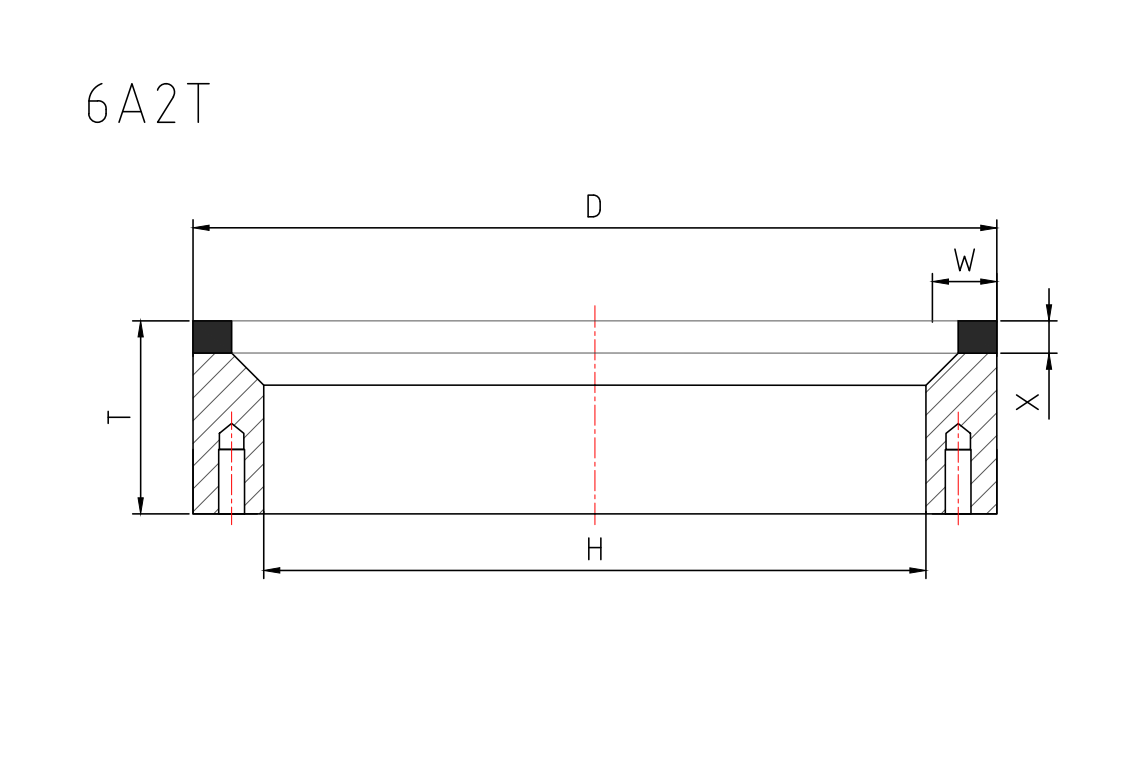

Grinding wheel parameters |

350X260X10X6X87T 8ASDC280K100B04 |

|

Insert material |

Carbide YS30 |

|

Insert model |

CNE454 |

|

Removal margin |

0.3mm |

|

Grinding cycle |

66 seconds / piece |

|

Grinding parameters |

grinding wheel linear speed 20m/s |

|

Dressing parameters |

Dressing wheel feed 0.03mm |

|

Parameters Trimming frequency |

grinding wheel linear speed 20m/s. |

|

Edge notch requirements |

chipping is less than or equal to 0.01mm. |

|

Wheel life |

3798 blades were ground and wheel consumption was 2.66mm. |

Resin peripheral grinding wheel second experimental parameters

|

Grinding wheel parameters |

350X260X20X6X87T 8ASDC280K100B04.

|

|

Insert material |

Carbide YG10 |

|

Insert model |

TNMX201324 |

|

Removal allowance on one side of the tool |

0.3mm. |

|

Grinding cycle |

130 seconds/piece (6 surfaces plus 9 arcs) |

|

Grinding parameters |

grinding wheel linear speed 20m/s |

|

Dressing parameters |

Dressing wheel feed 0.03mm |

|

Trimming frequency |

3 pieces/time |

|

Edge notch requirements |

chipping is less than or equal to 0.01mm |

|

Wheel life |

168 blades have been ground, and the wheel consumption is 0.14 |

Moresuperhard are focus on providing you high quality peripheral diamond grinding wheel(include basin bond,vitrified bond).We are willing to help you solve all the problems about insert grinding.

PCD tools need to be ground because after long-term use, the surface of the tool will accumulate cutting slag, wear and edge failure, resulting in a decrease in cutting performance. Grinding can restore the sharpness and geometry of the tool, extend its service life, and improve processing efficiency and quality.

Alumina ceramic has high hardness (HV1900~2100) and high brittleness (flexural strength 240~260MPa). It is a typical hard and brittle material that is difficult to machine. Its grinding processing cost is high, the efficiency is low, and the surface and subsurface after grinding Crack groups appear in the area, affecting the stability of the workpiece.Moresuperhard have rich experience in grinding ceramic materials and we can recommand suitable grinding wheels for you.Moresuperhard have development different formulations grinding wheel for different ceramics materials.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088