The methodology of measurement and what is measured when calculating Ra and Rz are quite different. This is critical to understand if you will not be paid for your parts because the Ra you measured is not in fact the Rz surface profile that customer specified.

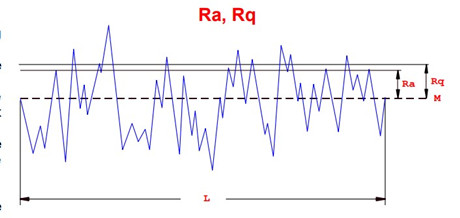

Ra is calculated by an algorithm that measures the average length between the peaks and valleys and the deviation from the mean line on the entire surface within the sampling length.

Ra averages all peaks and valleys of the roughness profile and then neutralizes the few outlying points so that the extreme points have no significant impact on the final results.

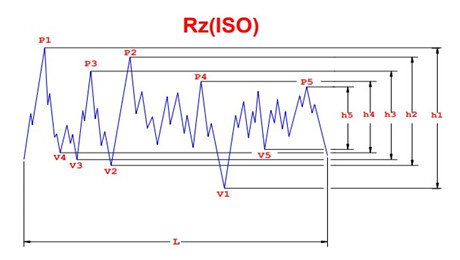

“Rz is calculated by measuring the vertical distance from the highest peak to the lowest valley within five sampling lengths, then averaging these distances. Rz averages only the five highest peaks and the five deepest valleys—therefore, extremes have a much greater influence on the final value.”

Ra is the arithmetical average value of all absolute distances of the roughness profile from the center line within the measuring length.

Rz is the average maximum peak to valley of five consecutive sampling lengths within the measuring length.

Ra averages all measurements and does not have any discriminating value in separating rejects from acceptable cylinders.”

When you want the better surface roughness of your parts, please feel free to contact More Super Hard, our experienced sales engineer will service for you.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Learn how to choose the right PDC cutters for deep and hard rock formations. Explore diamond thickness, thermal stability, impact toughness, cutter geometry, and bit design.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088