What is cemented carbide?

Cemented carbide is an alloy material made by powder metallurgy process of hard carbide (WC, TiC) of refractory metal and binder metal (Co or Ni or Mo).

Wide application of cemented carbide materials

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance. Cemented carbide has been widely used in aerospace, military industry, mechanical metal processing, metallurgy, oil drilling, building materials and other fields, and is used as tool material and handle and tool base material, such as turning tools, milling cutters, planers, drills etc., for cutting cast iron, non-ferrous metals, plastics, graphite, glass, stone and ordinary steel, and also for cutting heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult-to-machine materials.

China is a big country in the manufacture of cemented carbide materials and carbide inserts, with advanced, mature and stable technology, and it is also a big country in demand. The huge demand has caused fierce competition among various manufacturing companies, and they all demand to improve production efficiency and reduce the manufacturing cost of inserts.

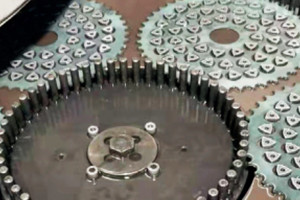

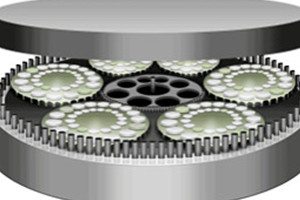

As a manufacturer of superabrasives, Moresuperhard provides customers with not only products, but also services, hard tools and PCD/PCBN/CVD tool grinding solutions. According to customer needs, Moresuperhard provides double-sided diamond and CBN (cubic boron nitride) grinding discs for batch grinding of workpieces like carbide inserts,pcd inserts,pcbn inserts.

Recently, a manufacturer of cemented carbide cutting tools approached Moresuperhard, hoping that we can help them improve the grinding production efficiency of cemented carbide inserts and reduce the production cost of single-piece cutting tools. Therefore, after full communication with the customer, Moresuperhard customized a pair of resin diamond grinding discs for testing according to the customer's requirements, and the customer was very satisfied with the test results.

Let's take a look at the test results:

| The brand of grinding disc | Moresuperhard |

| Dressing frequency | 18000ppd |

| Services life of grinding disc | 6000-8000 |

| Workpiece Surface Roughness | Ra0.15 |

Compared with the grinding disc used by the customer before, Moresuperhard's resin diamond grinding disc has outstanding performance, stable performance, high grinding efficiency, and a 20% increase in service life, thereby reducing the cost of the grinding wheel by about 20% for the customer's unit cost. As a whole, the cost of the customer's production line has been reduced by hundreds of thousands per year.

The successful application of resin diamond double-end grinding discs has helped customers greatly improve the production efficiency of tools and reduce production costs. Moao's double-face grinding disc has good stability, strict quality inspection, high grinding efficiency, and has received numerous praises.

<< :Advantages and disadvantages of wire drawing dies made of different materials

<< :MLED Industry Research Tour of China - Jiangsu/Anhui station successfully concluded

Customers use ceramic diamond cylindrical grinding wheels to grind PCD roller tools. At first, the customer was not satisfied with the chipping effect of using a domestic brand grinding wheel. Currently, customers use a resin diamond grinding wheel from a certain European brand to achieve better grinding results, but the cost is relatively high.

A diamond roller is a high-efficiency, long-life, low-cost grinding wheel dressing tool that uses electroplating or powder metallurgy methods to inlay a large number of diamond particles on the surface of a steel roller. It is used for special machine tools and gear grinders for mass form grinding. Rotating at a certain speed (thereby reducing the relative speed between the roller and the grinding wheel) produces grinding and rolling effects on the surface of the high-speed rotating grinding wheel, so that the grinding wheel obtains a sharp working surface that matches the roller profile.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088