Brazing processing of PCD inserts - high frequency induction brazing machine

The high frequency induction brazing machine has advantages of the induction heating speed, high efficiency, energy saving and low cost, the small oxidation area and the full solid welding, etc.

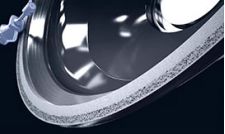

The brazing processing of PCD & PCBN inserts:

Step 1: Welding preparation

Welding powder, silver & copper foil , Pcd & Pcbn blanks, cutter body .

Between the cutter body and Pcd and Pcbn blanks put into the silver & copper foil and silver & copper powder .

*CBN Inserts with copper foil , 800~900℃

*PCD Inserts with silver foil , 750℃

Step 2 : High frequency induction welding machine

<< Prev Article:More SuperHard In A&G zhengzhou

<< Next Article:THE PRODUCTION TECHNOLOGY OF VITRIFIED BOND DIAMOND GRINDING WHEEL

LATEST NEWS

-

10 March 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

10 March 2020

Periphery grinding wheel

Diamond Wheels for Peripheral Grinding of inserts, must be o...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220