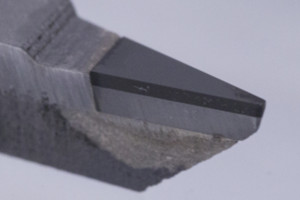

PCD or PCBN cutting tools have the highest qualityrequirements. Precise geometries and minimalchipping are the essential quality requirements.

6A2 vitrified diamond grinding wheel and peripheral diamond grinding wheel are commonly used for grinding PCD/PCBN cutting tools.The choice of grinding paraments is very crucial.

Recommand grinding paraments for grinding PCD tools and PCBN tools(grinding case)

6A2 vitrified diamond grinding wheel for grinding PCD cutting tools

| Diamond grinding wheel specifications | 6A2H 150*40*40 |

| workpiece | PCD mount plate |

| Grinding machine | Coborn R9 |

| Coolant | water |

| Stock | 0.3mm |

| Grinding Speed | 18m/s |

| Results | low wear chipping <10μm,10% less contace time |

Perpheral diamond grinding wheel for grinding PCD indexalbe inserts

| Diamond grinding wheel specifications | 12A2T 400*28*340 |

| workpiece | PCD -mounted plate |

| Grinding machine | Agathon 400 PENTA |

| Coolant | Blaser Grindlyte |

| Dressing interval | 6per cutting tools |

| Stock | 0.12mm |

| Grinding Speed | 25m/s |

| Results | 10% less wear Minimal chipping |

Moresuperhard manufactures a full line of insert grinding wheels for carbide, ceraric, cermet and PCD/PCBN materials.Diamond grinding wheels are designed with the optimal specifications considering the cycle time and dressing intervals for optimum praductivity. Moresuperhard diamond grinding wheel perforance is excellent, therefore, grinding inserts with a superior fnish and chip-free edge.

<< :Different Applications of CVD diamond plate

<< :what type of grinding wheels are used to grind pcd inserts?

PCD tools need to be ground because after long-term use, the surface of the tool will accumulate cutting slag, wear and edge failure, resulting in a decrease in cutting performance. Grinding can restore the sharpness and geometry of the tool, extend its service life, and improve processing efficiency and quality.

Alumina ceramic has high hardness (HV1900~2100) and high brittleness (flexural strength 240~260MPa). It is a typical hard and brittle material that is difficult to machine. Its grinding processing cost is high, the efficiency is low, and the surface and subsurface after grinding Crack groups appear in the area, affecting the stability of the workpiece.Moresuperhard have rich experience in grinding ceramic materials and we can recommand suitable grinding wheels for you.Moresuperhard have development different formulations grinding wheel for different ceramics materials.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088