What is CVD diamond?

CVD (Chemical Vapor Deposition) diamond refers to synthetic or lab-grown diamonds that are created through a process called chemical vapor deposition. Unlike natural diamonds that take millions of years to form deep within the Earth’s crust, CVD diamonds are produced in a controlled laboratory environment over a relatively short period of time.

The applications of CVD dimaond plate

CVD diamonds possess the same chemical and physical properties as natural diamonds. They have exceptional hardness, thermal conductivity, and optical transparency. CVD diamonds are used in various industries, including jewelry, electronics, cutting tools, heat sinks, and high-performance optics.

Applications of CVD diamond plate

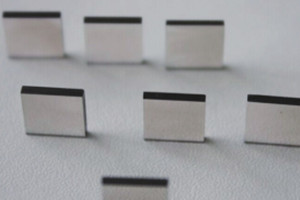

1.CVD diamond single wafer for cutting tool

CVD diamond has excellent wear resistance, Balanced fracture toughness and thermal stability for some applications Used to provide excellent cutting performance.Moresuperhard can provide high-quality CVD single crystal diamond products of various sizes (≤20mmx20mmx10mm) for diamond cutting tools, and the appearance and shape can be customized.

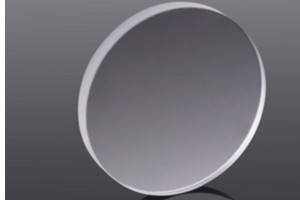

2.CVD diamond plate for optical windows

Optical-grade single-crystal diamond sheets are suitable for preparing emission windows and laser crystals for high-power lasers, lenses for high-power ultraviolet/infrared optical instruments, sensors and detectors that need to work in harsh environments, etc.The excellent performance of synthetic CVD diamond makes it suitable for Modern Optical Materials for Ultraviolet (UV) to Radio Frequency Transmission at its peak position.

3.CVD diamond plate for heat sink materials and Thermal pad

Unlike metals, heat conduction in diamond is dominated by Lattice vibration (phonon) control. The thermal conductivity depends on in the way of phonon scattering. In diamond, this is in the chamber temperature and phonon-phonon scattering (inverse process) and Defect/impurity scattering related. Polycrystalline CVD Diamond The grain size is above ~50 µm, the phase purity High, out-of-plane thermal conductivity changes less than in-plane thermal conductivity 10% of.CVD large single crystal diamond can be used in high-power lasers and microelectronic heat sink components.

4.CVD diamond plate for Terahertz window

It is suitable for preparing emission windows and laser crystals of high-power lasers, lenses of high-power ultraviolet/infrared optical instruments, sensors and detectors that need to work in harsh environments, etc.

5.CVD siamond plate for semi-conductor industry

Diamond is a wide bandgap semiconductor material, indirectly The band gap is 5.47 eV. For high-purity CVD Experiments with diamonds have shown that diamond has high mobility and long electron and hole lifetimes. plus High breakdown field strength and high thermal conductivity, which makes diamond become the material of choice for many demanding electronic applications material.

6.CVD diamond plate for Quantum application

CVD synthesis method can produce unintentional defect density in parts per billion (~1014 cm-3) or less synthetic diamonds. These diamonds have excellent broadband Gap electronic properties.

Moresuperhard is a diamond products from China.With international cutting-edge modern manufacturing technologies such as CVD, nano-manufacturing, and laser micro-superfinishing, we are committed to the R&D, production, sales, and service of diamonds, diamond tools, and related equipment.

<< :Why Choose SDC Abrasive for Resin Diamond Grinding Wheel?

<< :How to choose suitable grinding paraments for grinding PCD/PCBN tools?

PCD tools need to be ground because after long-term use, the surface of the tool will accumulate cutting slag, wear and edge failure, resulting in a decrease in cutting performance. Grinding can restore the sharpness and geometry of the tool, extend its service life, and improve processing efficiency and quality.

Alumina ceramic has high hardness (HV1900~2100) and high brittleness (flexural strength 240~260MPa). It is a typical hard and brittle material that is difficult to machine. Its grinding processing cost is high, the efficiency is low, and the surface and subsurface after grinding Crack groups appear in the area, affecting the stability of the workpiece.Moresuperhard have rich experience in grinding ceramic materials and we can recommand suitable grinding wheels for you.Moresuperhard have development different formulations grinding wheel for different ceramics materials.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088