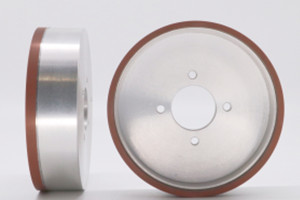

Case of grinding carbide cutting tools with resin diamond grinding wheel

workpieces of carbide cutting tools

Customer's requirements of diamond grinding wheel

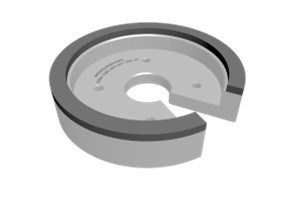

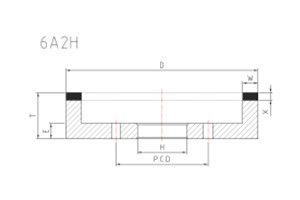

6A2H - D175*T28*H101.6*W8*X8 70%SD / 30%SDC 100J C100

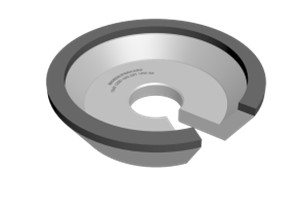

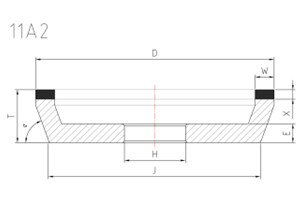

11A2 - D100*T40*H20*W5*X5 SD 800H C100 (Uncoated)

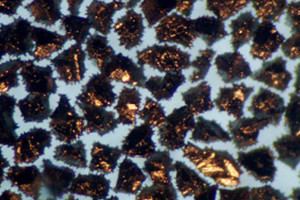

Moresuperhard provide resin diamond grinding wheel for customer to grind carbide cutting tools including rough grinding and fine grinding .As you can see,customer mention SDC Abrasives ,why we choose SDC diamond abrasives for machining resin diamond grinding wheel?

(1) Improve the bonding strength between the diamond abrasive and the resin bond, and the coating acts as a bonding bridge between the two.

(2) Slow down the heat shock. The metal coating diamond heat slower than the superhard abrasive, and the grinding heat is buffered by the coating and then transmitted to the resin bond in contact with the abrasive to prevent it from being burnt out due to the impact of instantaneous high temperature, thereby maintaining its holding force on the abrasive.

(3) Improve the particle strength of the abrasive. The coating plays the role of reinforcement and toughening. Due to the buffering effect caused by the thickness of the coating in electroless plating and electroplating, the strength of the three series of low, medium and high products is increased by 50%-100%, 50%-60% and 30% respectively.

(4) Thermal insulation protection. During high-temperature sintering and high-temperature grinding, the coating protects the diamond from rock desertification, oxidation or other chemical changes.

Moresuperhard is a diamond grinding manufacturer from China.Moresuperhard provide grinding solutions for cnc cutting tools including PCD cutting tools,PCBN Cutting tools ,carbide inserts,cermet cutting tools.If you need any help,please contact us freely.

Email:jason@moresuperhard.com

PCD tools need to be ground because after long-term use, the surface of the tool will accumulate cutting slag, wear and edge failure, resulting in a decrease in cutting performance. Grinding can restore the sharpness and geometry of the tool, extend its service life, and improve processing efficiency and quality.

Alumina ceramic has high hardness (HV1900~2100) and high brittleness (flexural strength 240~260MPa). It is a typical hard and brittle material that is difficult to machine. Its grinding processing cost is high, the efficiency is low, and the surface and subsurface after grinding Crack groups appear in the area, affecting the stability of the workpiece.Moresuperhard have rich experience in grinding ceramic materials and we can recommand suitable grinding wheels for you.Moresuperhard have development different formulations grinding wheel for different ceramics materials.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088