Causes and solutions of wheel breakage Part 2

5. Insufficient inspection of grinding machine or inappropriate machine tool

Problem 1: Loose bearings, bent main shafts, and precision of grinders are significantly reduced

Solution: Check and repair the grinder, and seek to improve its accuracy

Problem 2: The shaft diameter of the grinding wheel shaft is too small

Solution: If there is a grinding wheel with a size equivalent to the shaft, use a grinding wheel with this size

Question 3: Rough rough grinding or incorrect use of grinding wheels

Solution: Rely on the guidance of the skilled person or the manual of the grinding wheel to carry out the correct grinding operation

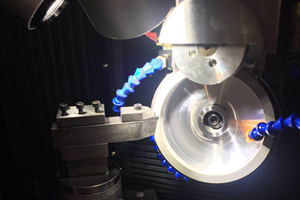

6. Side grinding with unsuitable grinding wheels

When using grinding wheels other than side grinding wheels, you must use grinding wheels (bowl wheels, etc.) for side grinding

7. Changes in grinding wheel quality

Question: When the grinding wheel encounters a flood or fire, the resin bond, rubber bond wheel, etc. have to change in quality

Solution: Confirm the entry way of the grinding wheel, correctly store it, consider the manufacturing date of the grinding wheel, and strictly carry out various inspections before use

8. Irregular damage

Problem: The quality of the grinding wheel is not good; the grinding wheel is pressed by heavy objects; the unreasonable installation of the grinding wheel

Solution: To ensure the quality of the product, enter the inspection to study its condition in detail and prohibit heavy objects from being pressed on the grinding wheel to install it smoothly.

<< Prev Article:Vitrified bond Diamond Wheel for PCD CBN Tools Grinding

<< Next Article:MYTECH 198NC is displayed in Tainan

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220