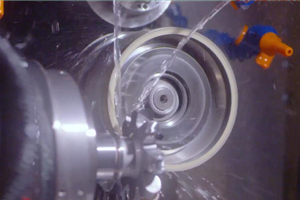

Creep Feed Grinding

2020-05-03 14:47:17

Creep Feed Grinding in the past there are many domestic names, such as power grinding, heavy duty grinding, peristaltic grinding, milling, etc., the current exact name should be slow feed deep grinding, Usually referred to as slow wear. The significant feature of this process is the low feed speed, which is about 10-3 to 10-2 times that of ordinary grinding. For example, the workpiece speed can be as low as 0.2mm / s during surface grinding, so it becomes a "slow" grinding. But on the other hand, the cutting depth is large at a time, which is about 100 to 1000 times that of ordinary grinding. For example, the limit cutting depth can be 20 to 30mm when flat grinding.

According to the theory of boiling heat transfer in the field of thermal engineering, the scientific explanation for the normal slow grinding temperature is very low but it is often prone to sudden burns. During the slow grinding, the heating conditions of the workpiece surface in the arc zone and the surface of the heated nickel wire immersed in the pool are essentially the same. The grinding fluid in the arc zone also has a critical heat flux density qlim that can cause film boiling. The so-called normal slow Grinding refers to grinding the heat flux density q <qlim. According to the previous analysis, this is because the grinding fluid is in the nucleate boiling state. It can absorb most of the latent heat of vaporization to remove most of the grinding tropical arc zone, so the surface temperature of the workpiece can be effectively controlled at the critical film formation of the grinding fluid The temperature qlim is below 120 ~ 130 ℃.

In other words, no matter how deep the cutting depth is, whether it is 1mm, 10mm, 20mm, 30mm, as long as the normal slow grinding conditions are met, the surface temperature of the workpiece in the arc zone will not exceed 120 ~ 130 ℃, which is also the difference between slow grinding process The advantages of ordinary grinding. However, this outstanding process advantage of slow grinding is actually easily lost due to the loss of heat flux control. Grinding heat flux density q is not only related to many factors such as material properties and cutting amount, but also largely depends on the sharpness of the grinding wheel surface. Therefore, in the original normal slow grinding process, the heat flux density is also easy to be blunt with the grinding wheel The breakthrough of the critical value is caused by the increase of chemical. In fact, it may sometimes be only a line separation. As long as the condition q ≥ qlim is met, the surface of the workpiece in the arc area will be suddenly burned by the grinding fluid entering the film-forming boiling state .

<< Prev Article:How to perform continuous dressing in creep feed grinding

<< Next Article:How to choose the appropriate grinding amount of grinding wheel?

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220