Matters needing attention when using diamond grinding wheel

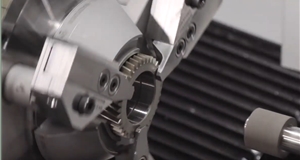

Diamond grinding wheel is the hardest grinding wheel, it has the ability of "indestructible", the grinding ability is very strong, but the use of diamond grinding wheel still need to pay attention to some matters. To extend the service life of diamond grinding wheel.

1. Diamond grinding wheel is a valuable tool, which is only used for processing high hardness materials, and should not be used for grinding general steel or other soft materials.

2. After flange is installed on diamond grinding wheel, it can only be used after static balance. It should be noted that the grinding wheel should not be removed from the flange casually before it is used up.

3. The machine tool with diamond grinding wheel has good rigidity, high precision of spindle selection (radial runout is no more than 0.01 mm), and can make trace horizontal feed.

4. The appropriate amount of grinding must be selected.

(1) Grinding wheel linear speed:

Metal bond:10~15*/ s (dry grinding), 20~35*/ s (wet grinding)

Resin bond:①15~30*/s(dry grinding),②25~40*/s(wet grinding)

(2) Workpiece linear velocity: 10~15*/ min.

(3) Grinding depth:The grinding depth should be small, otherwise the grinding wheel will wear quickly and the grinding efficiency may not be high. Generally with 0.005~0.01 mm/oxygen stroke is appropriate. The finer the abrasive size, the smaller the grinding depth should be, especially if the coolant is not used.

(4) Longitudinal feed speed: Generally it is 10~15 m/min. The coolant should be used as much as possible in grinding, which can not only improve the grinding efficiency and grinding quality, but also reduce the grinding wheel wear. Commonly used cooling fluid has light machine oil lamps, kerosene, light diesel oil, general with kerosene as well. A new diamond wheel began to use, in order to make it get the right shape (the circle roundness and straightness) face, also need to adjust, available silicon carbide grinding wheel dressing methods, or in silicon carbide abrasive on the flat sheet metal or glass by hand grinding for renovation (used for dressing grinding wheel face).

In order to save the expensive diamond grinding wheel, the method of natural dressing can also be adopted, that is, the new grinding wheel is first used for rough grinding, and then used for fine grinding after it is worn to the shape of securities.If the grinding wheel is not sharp enough or is blocked in the grinding process, you can also hold the silicon carbide grinding wheel to carefully repair the working surface of the grinding wheel.In addition, the following questions should be paid attention to:

1. Positive operation problem

In daily use, many operators are always used to operating directly against the grinding wheel, because this direction can be used to force, in fact, this behavior should be specially prohibited in the grinder operation. According to the operating rules, when grinding the workpiece with the grinder, the operator should stand on the side of the grinding wheel and should not operate on the front of the grinding wheel, so as to avoid the failure of the grinding wheel, the grinding wheel flying out or the grinding wheel broken flying out of the injury.

2. Side grinding problem

In the daily use of the grinder, we can often find that some operators, regardless of the type of grinder, regardless of the type of grinding wheel, the use of grinding wheel on the side of the grinding wheel, which is a serious violation of the safety operation rules of illegal operation behavior. According to the rules, it is not suitable to use the side grinding wheel to make the working surface with the circumferential surface. The radial strength of this kind of grinding wheel is large and the axial strength is small. If the operator USES too much force, the grinding wheel will be broken or even hurt.

3. Common operation problem

In the actual daily operation, there is also such a situation, someone in order to rush the production task, rush the work time, two people share a grinder operation at the same time, this is a serious violation of the operation behavior, should be strictly prohibited. When a grinder is not enough, can be used to add grinder solution, absolutely not allowed to share a grinder at the same time.

4. Force operation problem

In the use of the grinder, some operators, especially young operators, in order to find the speed of grinding, too much too hard, this is a very unsafe operation. The flat body of any grinding wheel has a certain degree of strength, which is likely to cause the grinding wheel to break, or even fly out and hurt people, which should be prohibited.

<< Prev Article:Applications of PCD and CBN tools

<< Next Article:Production process of diamond powder

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220