Cutting

Home / Cutting / PCD Cutting Machine > PCD Fiber Laser Cutting Machine

PCD laser cutting machine is developed for super hard materials, mainly used for diamond, PCD composite sheet, PCBN, CBN, ceramics, CVD and other cutting and processing.And can process multi-blade grinding head, multi-blade milling cutter, drill bit, tooth cutter, special-shaped grinding head, PCD cutter, CBN cutter, PCBN cutter, etc. The finished products can be used in the processing of spherical cutter, ball milling cutter, forming cutter, chamfer cutter, round nose cutter, drill bit, tap and other super hard cutting tools.

The principle of laser cutting PCD is that a laser beam with extremely high energy density irradiate the surface of polycrystalline diamond, and part of the light energy is absorbed by the surface and converted into heat energy. The local temperature of the irradiation spot rises rapidly to tens of thousands of degrees, which makes the polycrystalline diamond material melt or even vaporize locally and form pits.

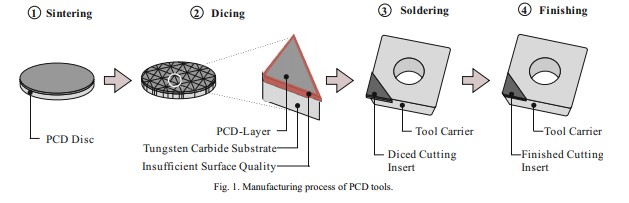

The manufacturing process of PCD tool is described in the following figure:

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

The finer the grinding wheel particle size, the smaller the cutting edge chipping, and the lower the grinding efficiency. For this reason, the PCD cutting tool sharpening process can be divided into three processing stages: coarse, fine, and fine according to the accuracy of the cutting edge of the tool, its purpose (see Table 1) or its failure degree (see Table 2). Formulating a reasonable sharpening process according to specific conditions can greatly improve processing efficiency.

MORESUPERHARD can not only provide you with efficient double surface fine grinding solutions, but also provide you with dressing solutions matching your double side grinding machine !

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088