Brazing

Home / Brazing / Diamond Brazing Machines > Rapide Vacuum Brazing Machine

Vacuum Brazing Machine is capable of welding excellently between super hard materials and T/C ceramics, all kinds of Diamond also easy to braze at high speeds.

Materials : Diamond, Artificial Diamond, PCD, PCBN, CVD, Cermet,·

Substrates materials : Cermet( WC,Tic-based cermet), Steel, Steel alloy, Stainless Steel, Ceramic, Other Diamond.

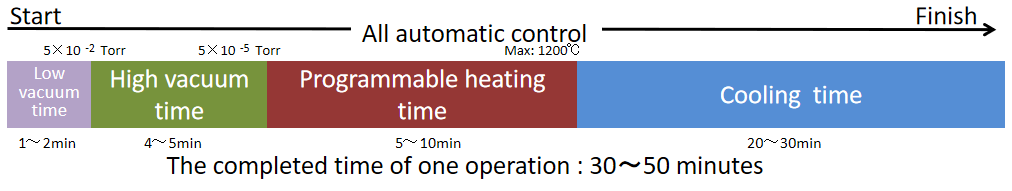

The system spec of this vacuum brazing machine

The characteristic of rapide vacuum brazing machine

●Rapid

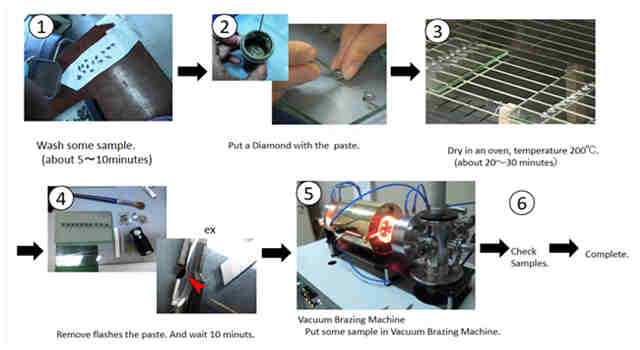

●Easy to operate

The brazing process of vacuum brazing machine differs from conventional brazing, operating rapid vacuum brazing machine nearly do not require skill.

●Braze strongly

The chamber inside vacuum level is over 5×10 torr and it prevents a diamond from burning, and Keeps clean inside chamber.

All products inside chamber can be brazed under same atmosphere. So all brazing metals of products are same beautifully glossy showing after brazing.

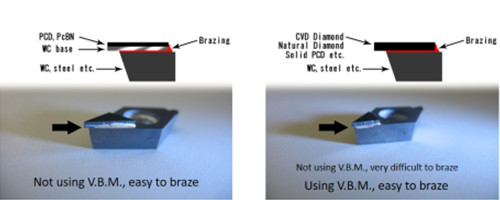

● CVD diamond and Natural diamond also can be brazed using rapid brazing machine

By using vacuum brazing machine it is possible to braze CVD/natural diamond, solid PCD (PCD without carbide substrate), ceramics, etc.

The advantage of vacuum brazing machine

・ No oxdation

・Cleaning the base metal surface

・Degassing of the base metal and the paste

・Low heat indication

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088