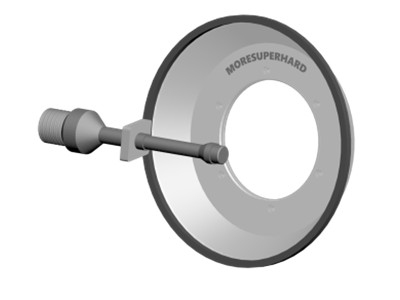

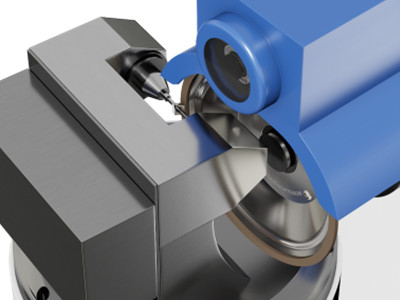

Diamond peripheral grinding wheels are used for peripheral grinding of PCD, CBN, carbide, ceramic, cermet and other indexable blades, flat blades, milling cutters, cutting blades, brazing blades, and machine clamp blades. At present, Moresuperhard peripheral grinding wheels have been successfully equipped with domestic and foreign mid-to-high-end peripheral grinding machines such as Hypertherm, Tiantong, Weize, WAIDA, EWAG, AGATHON, and WENDT, and have received unanimous praise from customers.

1. There is almost no clogging during the grinding process and no need for trimming;

2. The cutting edge of the grinding workpiece has consistent quality and high smoothness;

3. The grinding efficiency is 30%-50% higher than that of its peers, and the service life is increased 2-3 times;

4. Magnified 300 times under the tool microscope, the chipping of the blade can be controlled within 3 μm;

5. It can comprehensively improve grinding wheel performance, save manpower, improve processing efficiency, minimize production loss and downtime, and truly help customers reduce costs and increase efficien

| Moresuperhard vitrified peripheral diamond grinding wheel | Other vitrified diamond peripheral grinding wheel | |

| workpieces | CCGW-PCD inserts | |

| Dressing | No dressing required after install | The grinding wheel has runout after installation and needs to be dressing |

| Single inserts grinding time | 3 minutes and 6 seconds | 4 minutes and 25 seconds |

| Abrasive layer consumption of a single blade | 0.023mm | 0.045mm |

| Number of blade grinds in four hours | 50pcs | 30pcs |

| Grinding wheel speed | 2500 | 1500 |

The peripheral grinding wheel used by the customer before was worn out quickly and had to be trimmed frequently, so it needed to be improved. Under the same grinding conditions, the MORESUPERHARD peripheral grinding wheel requires almost no dressing, the efficiency is increased by 31%, and the grinding wheel life is doubled.

The customer originally used European brand grinding wheels, which had low grinding efficiency. The efficiency of using Moao peripheral grinding wheel is doubled.

| Workpieces | unstandard PCD inserts |

| Grinding machine | EWAG |

| Grinding Wheel specifications | D200*H40*T50*W5*X10 |

| Total number of sharpening tools per grinding wheel | 1430 |

| Single inserts grinding time | 8minutes |

| Abrasive layer consumption of a single blade | 0.007mm |

| Grinding efficiency | Under the same grinding conditions, the Moresuperhard peripheral grinding wheel is twice as efficient as the previous grinding wheel. |

| Grinding wheel services life | 50% improvement compared to the original grinding wheel |

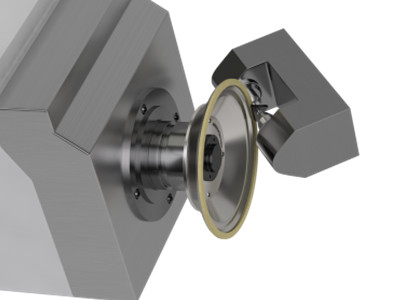

Customers can grind the same type of PCD, CBN, ceramic, cermet, alloy blades, cuttingtools, or parts, but if you buy a different peripheral grinder, the grinding wheel will be different, and the particle size of peripheral grinding wheel you buy will be slightly different. There are differences, mainly in the diameter of the grinding wheel, the way the grinding wheel is fixed, and the rotation speed is not necessarily the same, but in the end they can all grind the same type of blade. Since its establishment, Moresuperhard has been exclusively providing users with complete solutions as a system supplier. Develop correct and professional grinding solutions for each of users' needs, helping users to respond quickly to changing customer needs and consolidate their market position.

If you encounter grinding problems, Moresuperhard can provide you with the fastest solution and the most suitable grinding products to help customers reduce costs and increase efficiency. Moresuperhard has been taking action. So, how many customers around the world can ultimately be helped to save more time and production costs? Let’s wait and see! !

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088