Brazing

Home / Brazing / Diamond Brazing Machines > high speed vacuum brazing machine

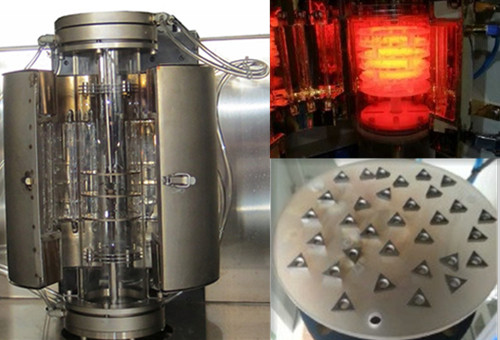

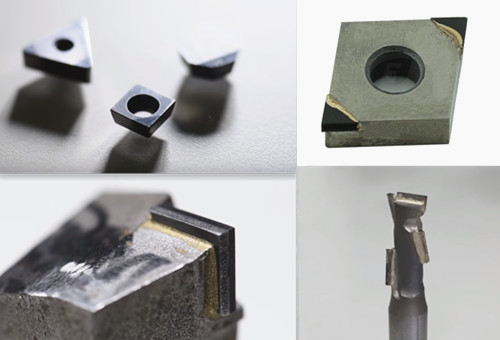

vacuum brazing machine is excellent for welding between superhard materials, tungsten carbide, ceramics and all kinds of diamond.The materials include ND (natural diamond),Synthetic Mono crystal diamond,CVD diamond,PCD/PCBN and cermet,etc.

vacuum brazing is often conducted in a vacuum chamber, this means that several joints can be made at once because the whole workpiece reaches the brazing temperature. vacuum brazing method realizes a shorter construction period, work environment improvement, enhancement of strength due to degassing and reduction of distortion due to wholly heating. The advantages include:

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088