Cutting

Home / Cutting / Tool Blanks > CVD Diamond Dressing Tool Blank

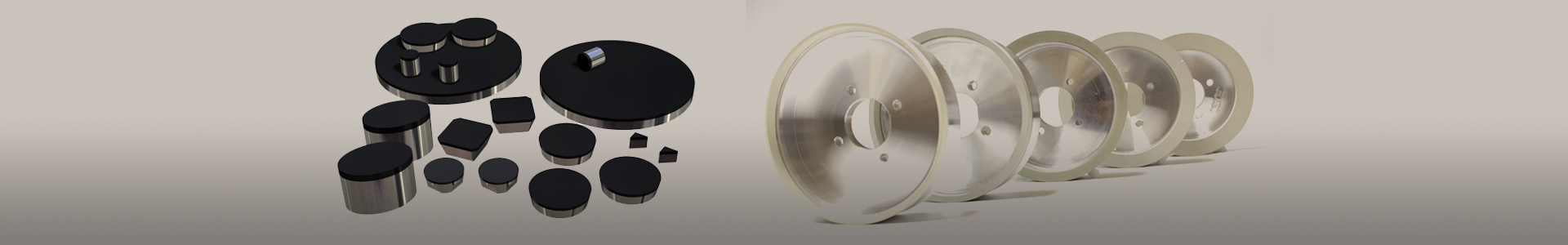

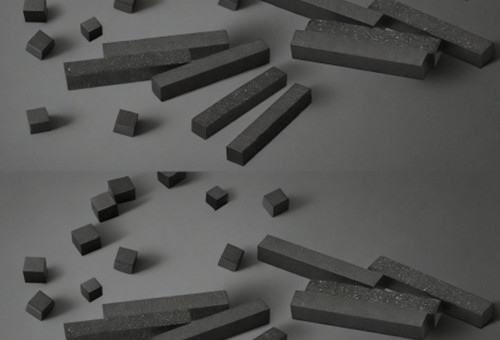

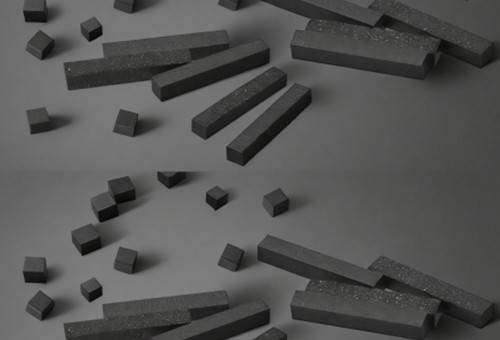

Our company's CVD dressing tool blanks are made of pure polycrystalline diamond, containing no binders and exhibiting no hardness-softness difference, resulting in highly stable performance. The products possess extremely high hardness, wear resistance, and thermal stability, are not easily broken, and have a wear ratio of 200,000–1,800,000. When used for dressing grinding wheels, they effectively improve wheel sharpness and workpiece surface finish, making them a superior alternative to natural diamond and single-crystal diamond.

High-purity polycrystalline structure, no metal catalyst

Possesses stable thermal and physical properties, close to those of natural diamond.

No brittle cleavage planes, strong impact resistance

Disordered grain arrangement, not easily broken, suitable for high-load dressing conditions.

High hardness, superior wear resistance

Wear ratios range from 200,000 to 1,800,000 depending on the grade, long lifespan, and high stability.

Excellent dressing effect

The dressing wheel remains sharp after dressing, significantly improving the surface finish of the workpiece.

Alternative to natural and single-crystal diamond

More stable performance and more cost-effective, making it an ideal blank material for various dressing tools.

Suitable for manufacturing various high-performance grinding wheel dressing tools,

including: Single-point diamond dressing pens Multi-point grinding wheel dressers Diamond dressing rollers Shaping and dressing tools Shaping and sharpening of various ceramic, resin, and metal-bonded grinding wheels.

| Item | Natural Diamond | CVD Diamond |

| Hardness(GP) | 100 | 70-100 |

| Density(g/cm³) | 3.515 | 2.8-3.5 |

| Melting Point (C°) | 4000 | Nearly 4000 |

| Elastic Modulus(Gpa) | 1.04*1012 | 1.04*1012 |

| Young's Modulus (Gpa) | 1200 | 1050 |

| Thermal Shock Coefficient(W/m) | 107 | 107 |

| Coefficient of Friction | 0.08-0.1 | 0.08-0.1 |

| Frature Toughness (Mpa.m1/2) | Nearly 3.4 | 1.8 |

| Tensile Strength (b/Gpa) | Nearly 3.0 | 0.2-0.4 |

| Coefficient of Thermal Expansion (X10-6/k) | 1.0(300k) | 1.0(300k) |

| 2.7(500k) | 2.7(500k) | |

| 4.4(1000k) | 4.4(1000k) |

| Specifications | L(mm) | W(mm) | T(mm) |

| CVD L*W*04 | L | W | 0.4 |

| CVD L*W*06 | L | W | 0.6 |

| CVD L*W*08 | L | W | 0.8 |

| CVD L*W*10 | L | W | 1.0 |

| CVD L*W*15 | L | W | 1.5 |

| CVD L*W*20 | L | W | 2.0 |

Note: Single-sided or double-sided polishing is available. Custom shapes and sizes can be cut to customer specifications.

Available Services

CVD Diamond Cutting and Shaping

Single/Double-Sided Fine Polishing Service Custom Shapes (Round, Square, Irregular)

Small Batch Trial and Mass Production Supply

Technical Support for Grinding Wheel Dressing Solutions

Ordering Information

Please provide the following information to confirm specifications: Dimensions (Length × Width × Thickness) Grinding Grade Required (Abrasion Ratio Range) Polishing/Shaping Required Application (Single-point, Multi-point, Shaping Tool, Roller, etc.)

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088