PCD (Polycrystalline Diamond) saw blades, known for their ultra-high hardness, outstanding wear resistance, and superior cutting precision, play an indispensable role in high-end cutting applications such as woodworking, composite materials, and aluminum alloys. However, the inherent properties of PCD—extreme hardness and brittleness—place stringent demands on machining equipment and processes. As a non-traditional machining technology, Electrical Discharge Machining (EDM), with its unique working principle, demonstrates irreplaceable advantages in PCD saw blade manufacturing, effectively overcoming the limitations of conventional processing methods.

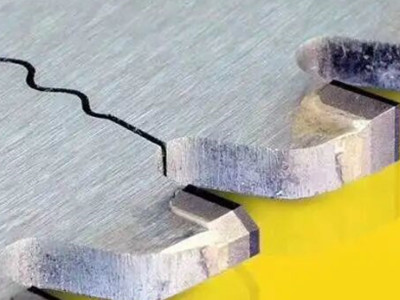

EDM is essentially a machining process without cutting forces. Its core principle relies on pulsed electrical discharges between the electrode and the workpiece, generating localized high temperatures that melt and vaporize material for removal—without any mechanical contact between the electrode and the PCD material. This characteristic is particularly critical for PCD, which is both extremely hard and brittle. In conventional mechanical grinding, the compressive and cutting forces exerted on PCD saw teeth often lead to chipping, cracking, or micro-fractures, severely compromising tool performance and service life. By completely eliminating mechanical stress, EDM preserves the intrinsic properties of PCD, ensures the structural integrity of saw teeth, and significantly reduces the scrap rate.

EDM is insensitive to material hardness. Regardless of how hard the PCD material is, as long as electrical conductivity is ensured (typically via a conductive substrate), precise machining can be achieved. This advantage is difficult for traditional grinding processes to match. In practical applications, PCD saw blades are often designed with complex tooth profiles, special geometries, fine tooth pitches, or unique rake and clearance angles to meet different cutting requirements. Such structures cause severe tool wear and poor dimensional control when processed by conventional methods. EDM, however, enables precise machining of complex tooth geometries through accurate control of pulse parameters and electrode paths, without being constrained by material hardness—greatly expanding the design freedom of PCD saw blades.

The cutting stability and service life of a PCD saw blade are closely linked to the consistency of tooth profile, pitch, and height. Leveraging high-precision CNC control systems, EDM achieves micron-level accuracy, faithfully reproducing tooth geometry as defined in the design drawings. Variations in tooth contour, pitch, and height across the blade can be minimized to extremely tight tolerances. This high level of consistency ensures uniform cutting forces during operation, reducing vibration and localized wear. As a result, cutting accuracy, surface quality, and overall blade lifespan are significantly improved—meeting the stringent stability requirements of high-end cutting applications.

Different applications impose varying requirements on PCD saw blade thickness and structural design. High-end blades may feature thick PCD layers, fine or high-density tooth patterns, or even multi-layer composite structures combining PCD with other materials. EDM offers exceptional adaptability to both PCD thickness and structural complexity. By optimizing discharge parameters and electrode design, EDM can stably machine everything from thin to thick PCD layers, while precisely processing interfaces in composite structures without causing delamination or damage. This wide adaptability allows manufacturers to meet highly customized demands across industries without frequent equipment or process changes.

Compared with laser processing or traditional grinding, EDM delivers superior tooth integrity when machining PCD saw blades. While laser cutting offers high speed, it often introduces heat-affected zones that degrade PCD performance, necessitating additional post-processing such as regrinding or profiling. Traditional grinding, on the other hand, involves complex procedures, rapid tool wear, and long machining cycles. EDM produces clean tooth profiles with excellent surface quality, requiring little to no secondary finishing to meet application requirements. This significantly shortens production cycles, reduces process steps and labor costs, and markedly improves overall manufacturing efficiency.

Thanks to these core advantages, EDM-machined PCD saw blades demonstrate outstanding competitiveness in high-value and precision cutting fields. In woodworking, they enable high-precision cutting of hardwoods and premium timbers with smooth, burr-free edges. In composite material processing, EDM-produced PCD blades effectively handle carbon fiber and glass fiber materials, preventing tearing and delamination. For aluminum alloys and precision sheet materials, they deliver efficient and accurate cutting that meets the demanding tolerance requirements of industries such as automotive and electronics manufacturing. By leveraging EDM technology, PCD saw blades can be tailored for a wider range of high-end applications, driving continuous improvements in machining quality across industries.

In summary, EDM-based manufacturing of PCD saw blades effectively addresses the inherent machining challenges of PCD materials through non-contact processing, high-precision control, and broad adaptability. At the same time, it simplifies production workflows and enhances efficiency, providing a reliable and high-performance solution for the manufacture of premium PCD saw blades. With ongoing advancements in CNC and EDM technologies, their application in PCD saw blade machining will continue to expand, further accelerating technological innovation and development in the precision cutting industry.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088