Single crystal diamond produced by CVD has high thermal conductivity

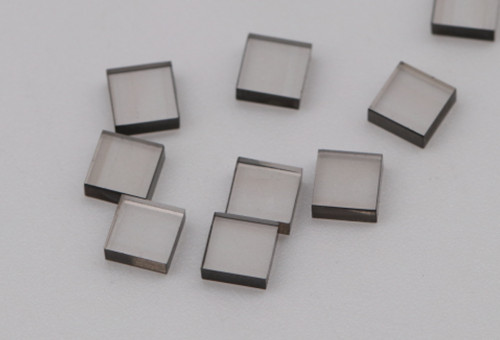

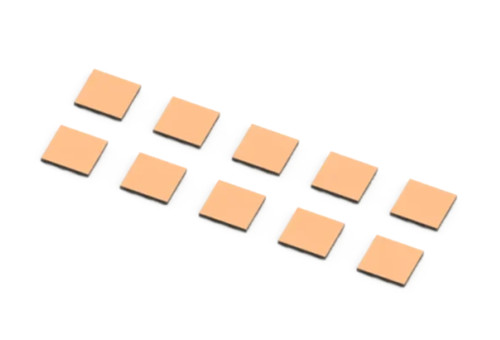

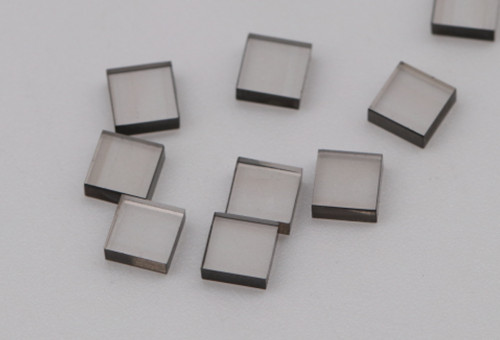

We can provide high-quality CVD single crystal diamond heat sinks in various sizes (≤20mmx20mmx1mm), with customized appearance and shape.

The thinnest thickness can be processed to 0.05 mm, and the surface roughness is less than 10 nm

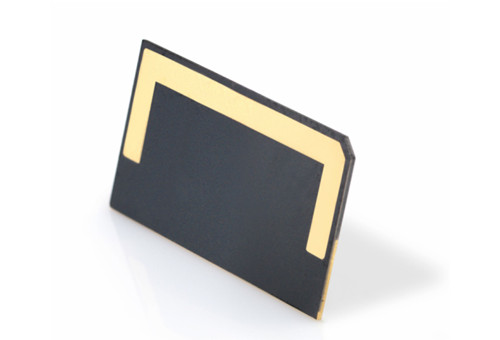

Applications:High Power Laser Diodes and MCMs

Provide polished CVD diamond plate

CVD diamond materials characteristics

CVD (Chemical Vapor Deposition) single crystal diamond is a synthetic material with excellent properties. Its high thermal conductivity, low thermal expansion coefficient and excellent mechanical strength make it an ideal heat dissipation material for high-performance electronic equipment. CVD single crystal diamond heat sink material is made through advanced chemical vapor deposition technology and has excellent thermal management capabilities, which can significantly improve the performance and reliability of electronic components.

The thermal properties of diamond

The thermal properties of diamond are reflected in its extremely high thermal conductivity. At room temperature, its thermal conductivity is 1000~2000w/m.k, which is 3~5 times that of copper materials. It is much higher than the thermal conductivity of currently used materials such as aluminum nitride, Cu-W alloy, aluminum oxide, and beryllium oxide, and is second only to natural lla type and high-pressure synthesized Ib high-quality single crystals. In addition, it has a very small thermal expansion coefficient and is a very good insulating material. Therefore, CVD diamond currently has an irreplaceable advantage in high-power semiconductor thermal management.

CVD diamond heat sink material has the following advantages

• Improve reliability and efficiency by reducing equipment operating temperature

• Reduce system weight and footprint

• Reduce or eliminate auxiliary cooling systems

Single crystal CVD diamond heat sink material information

| Nitrogen content | <50ppm |

| Young's modulus | 1150-1300Gpa |

| Hardness (microhardness) | 80-150Gpa |

| Friction coefficient |

0.05-0.5 |

| Thermal expansion coefficient | 10-6·K-1 |

| Thermal conductivity | 1500-2000w/(m.K) |

|

Specification |

Parameter |

|

Size |

1–6 inch, customizable |

|

Thickness |

0.25–1 mm, customizable |

|

Surface Roughness |

< 10 nm |

|

Thickness Tolerance |

±0.03 mm |

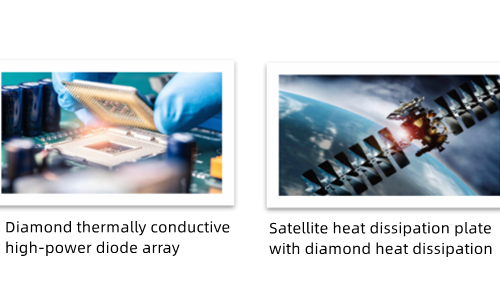

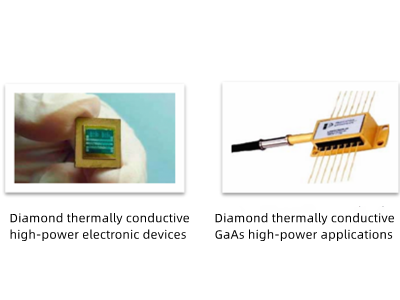

Diamond heat sinks can be used in thermal management components of optical communications, chips, laser diode arrays, 5G base stations, aerospace, high-power electronic devices, etc.

High-performance electronic packaging: Diamond thermally conductive materials are used in high-end electronic devices such as CPUs and GPUs to rapidly conduct heat away from the chips, effectively preventing heat buildup.

Laser equipment heat dissipation: In industrial laser processing equipment, diamond heat sinks are used in critical components of lasers.

5G communication base stations: Diamond heat sinks are used in power amplifiers and other equipment in 5G base stations. New energy vehicles: In the new energy vehicle sector, diamond thermally conductive materials have important applications in battery heat dissipation.

Artificial intelligence: High-performance computing platforms in the field of artificial intelligence require efficient heat dissipation systems to support large-scale parallel computing. Single-crystal diamond heat sinks provide excellent heat dissipation performance, ensuring the stable operation of computing platforms.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088