PDC Cutter(Polycrystalline Diamond Composite)

Polycrystalline Diamond Compact (PDC) cutters are widely used in demanding applications such as oil drilling, natural gas extraction, and geological exploration. Known for their extreme hardness and wear resistance, PDC cutters require high-performance grinding tools for effective processing. Moresuperhard recommends ceramic bond diamond grinding wheels for the rough grinding of the cylindrical surface of the diamond layer on PDC cutters. These wheels demonstrate excellent efficiency and cost-effectiveness compared to traditional resin bond wheels.

Applications of PDC Cutters

1. Oil and Gas Drilling Used in deep well drilling for petroleum and natural gas.

2. Geological Exploration Efficient in breaking through rock layers for mineral or structure detection.

3. Energy Mining Applied in coal, shale gas, and similar resource extraction.

4 .Geothermal and Tunnel Drilling Suitable for high-stress, high-impact environments such as geothermal boreholes and tunnel boring machines.

Advantages of Grinding PDC Cutter with vitrified bond diamond grinding wheel

1. Higher Grinding Efficiency Ceramic bond wheels have superior hardness and grinding power, which allows faster material removal from the PDC surface, significantly reducing the grinding time per cutter.

2. Better Dimensional Accuracy Ceramic wheels maintain their shape during grinding, helping to improve the consistency and dimensional precision of each PDC cutter.

3. Lower Overall Cost Due to their longer lifespan, ceramic bond diamond wheels offer a lower cost per piece, making them ideal for high-volume production.

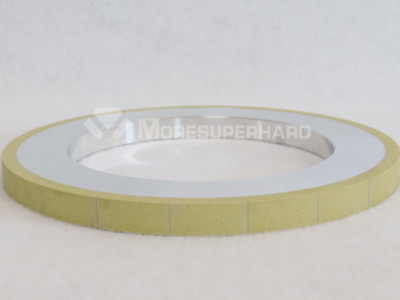

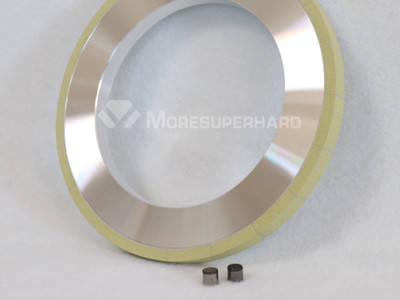

Moresuperhard offers a range of ceramic diamond grinding wheels

Common specifications include: 1A1 Shape

Ø350×40×127×10 mm

Ø400×40/50×203×10 mm

Ø400×40/50×305×10 mm

Common Grit Sizes 140/170 170/200

Grinding Performance of vitrified diamond grinding wheel for PDC Cutter

A Ø400 mm diameter, 50 mm thick, 11 mm rim width ceramic grinding wheel can grind approximately 200–300 oil-grade PDC cutters. When used for standard geological cutters, one wheel can process from 1,000 to over 10,000 pieces, depending on cutter quality, composite layer thickness, and product variations from different manufacturers.

Moresuperhard ensures performance, consistency, and cost-efficiency. For customized solutions for your PDC cutter grinding needs, please contact Moresuperhard for expert support and high-performance ceramic diamond wheels.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088