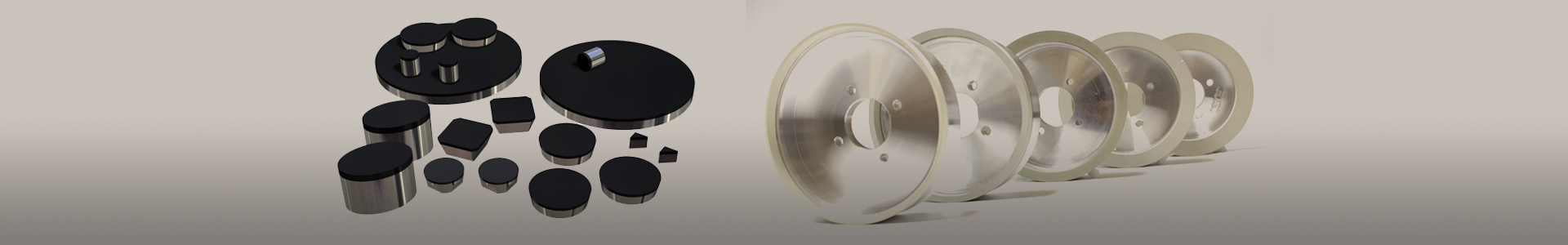

Polycrystalline Diamond Compact Cutter

Appliactions:Coal mining, geological exploration, oil and gas drilling,mining tools

Specifications:0808,0908,1313...2513 etc

Classifications:Standard PDC cutter and shaped PDC cutters

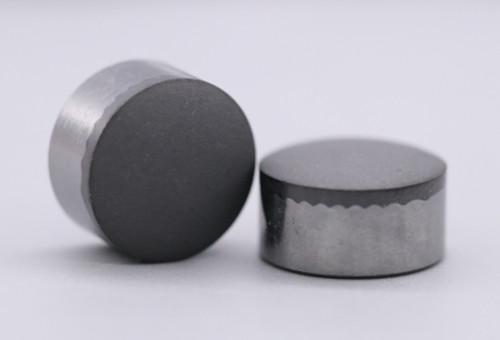

What is PDC cutter?

Polycrystalline diamond composite (PDC) is a super-hard composite material made of artificial diamond powder, binder and cemented carbide matrix that are sintered at one time using a six-sided press machine under high temperature and ultra-high pressure conditions. The high wear resistance and high impact resistance of cemented carbide make it adaptable to processing in various complex working conditions. The PDC drill bit made of it not only greatly improves the life of the drill bit, but also significantly improves the drilling performance of the drill bit. Improve efficiency and are currently widely used in coal fields, geology, oil, natural gas and other fields.

Applications of PDC cutters

PDC cutter for oil and gas drilling

Pdc cutter for oil/gas drilling has the characteristics of high wear resistance, high impact resistance and high thermal stability. As the drill bit cutting teeth for oil/gas drilling projects, its performance must not only meet the drilling needs of complex formations such as drilling in soft to extremely hard formations and passing through hard interlayers, but the various shapes of the composite piece can also greatly improve the drilling speed and optimize the adaptability of the drill bit to various downhole working conditions, and widely serve the mid-to-high-end drill bit drilling market.

PDC cutter for coal mine drilling

Made of selected high-quality diamond and cemented carbide sintered under high temperature and high pressure, it is specially designed and manufactured for coal field/mine drill bits. This product has the advantages of fast footage, high efficiency, less chipping and economical and practical, and is designed and developed to meet the comprehensive needs of cost and efficiency. It is widely used in geological exploration, coal field drilling and mining drill bits and mechanical processing tools, and is mainly used in the manufacture and application of coal mine and mine drill bits.

PDC cutter for Underreamer

PDC cutters for underreamers are engineered for extreme downhole environments. With high impact resistance and superior wear performance, they ensure efficient enlargement of wellbores in oil and gas drilling. The cutters maintain cutting efficiency in high-temperature and high-pressure formations, reducing tool failure and extending service life.

PDC cutter for PDC Bearings

PDC cutters used in PDC thrust and radial bearings provide excellent wear resistance, thermal stability, and low friction. Ideal for harsh drilling conditions, these cutters reduce wear on bearing surfaces, ensuring long-lasting, smooth rotational performance. Precision manufacturing guarantees consistent performance under heavy axial and radial loads.

PDC Cutter for Shield Machine(TMB)

PDC cutters for shield machines (tunnel boring machines) are designed to withstand the demanding cutting of hard rock and mixed ground. They offer outstanding toughness and abrasion resistance, ensuring longer tool life and reduced downtime. These cutters help improve excavation speed and maintain cutting accuracy in complex geological conditions.

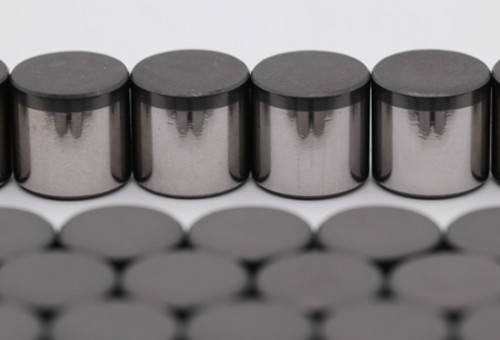

Specifications of PDC cutters

| Specifications | Diameter(±0.03) | Height(±0.10) | Diamond Layer Thickness(±0.10) |

| 0808 | 8.20 | 8.0 | 1.5-2.2 |

| 0908 | 9.0 | 8.0 | 1.5-2.2 |

| 1008 | 10.0 | 8.0 | 1.5-2.2 |

| 1108 | 11.02 | 8.0 | 1.5-2.2 |

| 1308 | 13.44 | 8.0 | 1.5-4.0 |

| 1313 | 13.44 | 13.2 | 1.5-4.0 |

| 1613 | 15.88 | 13.2 | 1.5-4.0 |

| 1913 | 19.05 | 13.2 | 1.5-4.0 |

| 1916 | 19.05 | 16.00 | 1.5-4.0 |

| 2513 | 25.4 | 13.2 | 1.5-4.0 |

Standard PDC Cutter

Conical Shaped PDC Cutter

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088