Cutting

Home / Cutting / PCD Cutting Machine > Precision Drawing Die Punching Machine

Hole diameter: 0.03 mm minimum – unlimited maximum

Thickness range: 0.1 – 40 mm

Smooth inner hole walls,fast drilling speed,automatically completes micro-hole forming in drawing dies

Stable, efficient, and accurate for all wire drawing die applications like PCD,CVD,MCD and Carbide

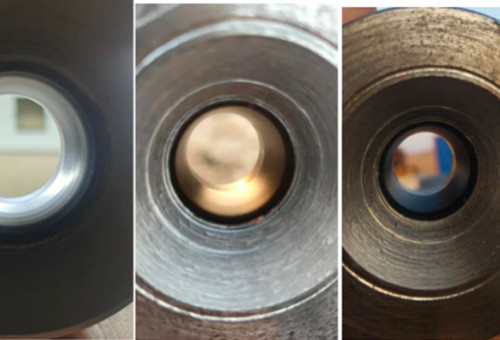

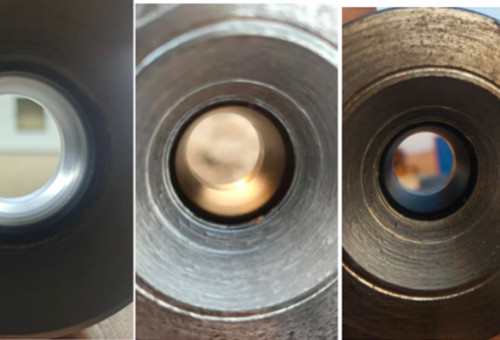

Precision laser punching machine is used for laser punching of superhard materials such as diamond and ceramics.

The laser punching machine is composed of fiber laser (semiconductor pumped laser), laser power supply, laser focusing system,CCD monitoring system, precision worktable, laser chiller,driving system,computer control system and punching software, to realize the whole process of laser wire drawing die punching processing. For diamond drawing dies, the minimum punching hole diameter is 0.03mm, the maximum hole diameter is not limited (the core punching method can be used), and the punching thickness is 0.1-40mm.

Configuration of Wire Drawing Die Punching Machine

| Model | MLS-60-500 | |

| Powder | 220V,50-60Hz | |

| Laser Type | Fiber Laser(1064nm) | |

| Maximium laser output power | 60-500w | |

| Spot Diameter | 0.03-0.008nm | |

| Laser Frequency | 1Hz-4000KHz | |

| Device Stability | 20hours of continuous | |

| Focus the lens | F=50-150mm | |

| Motorized diaplacement table | X150,Y50,Z200 | |

| Motor | Stepper motor (optional servo motor) | The X-axis can be used witha marble base linear motor |

| Drive | ≤3um | |

| Repeatable positioning speed | 5mm/s | |

| Diaplacement table center load | 10Kg | |

| Spindle Accuracy | Runshaft≤3um | |

| Frock | CHANDOX tight chock | |

| Yaw Shaft | planetary reducer(crossed roller bearing)accuracy ±0.5° | |

| Punching Software | Process | |

| Real-time monitoring system | Coaxial CCD,Box with reticute CCD 80x | |

| Power consumption of machine | 2.5kw | |

| Punching Method | Yaw rotary punching method | |

| Punching Dimeter | 0.3-50mm | |

| Punching Accuracy | ±0.01mm | |

| Punching thickness | 0.1-40mm |

MLS Series Drawing Die Punching Machine

| Model | MLS-100 | MLS-200 | MLS-300 | MLS-500 |

| Laser power | 100W | 200W | 300W | 500W |

| Laser Wavelength | 1064nm | |||

| Pluse frequency | 0.4-3MHz | 0.13-3.0MHz | 0.13-12MHz | 0.4-3.0MHz |

| Set pluse width range | 1-50ns | |||

| Punching Diameter | 0.1-2mm | 0.2-40mm | 0.4-40mm | 0.4-40mm |

| Punching thickness | 0.1-5mm | 0.1-40mm | 0.1-40mm | 0.1-40mm |

| Punching Method | Yaw rotary punching method | |||

Green Light Series Wire Drawing Die Punching Machine

| Laser Wavelength | 532nm |

| Pluse Frequnency | 0.5-10KHz |

| Punching Diameter | 0.03-1mm |

| Punchining Thickness | 0.1-2mm |

| Punching Method | Yaw rotation punching+Rotating gradul punching |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088