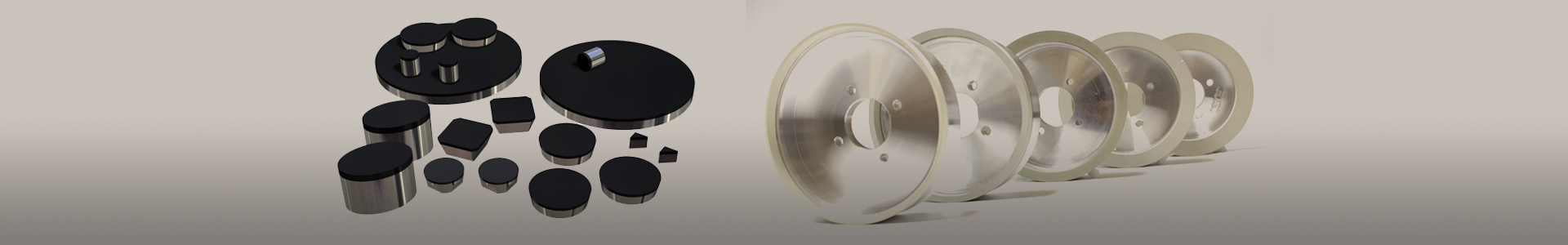

Products types:Pt/Ti Anode and Lead Alloy Anodes

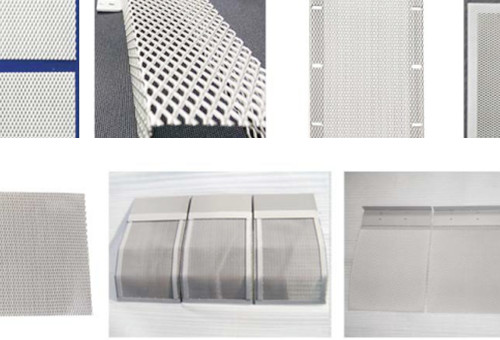

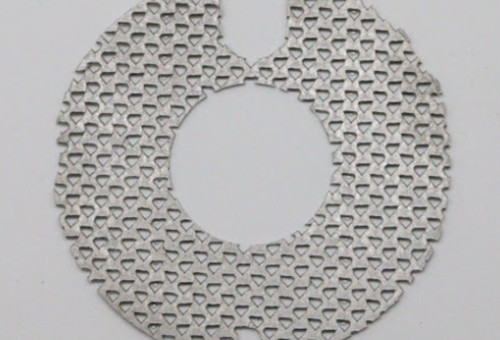

Shapes:Plate, mesh, tube, wire, or special-shaped parts;

Applications:Electroplating, electrolysis, cathodic protection

We offer a range of electroplating anodes, including lead alloy anodes and platinum-coated titanium anodes (Pt/Ti anodes). These anodes are widely used in electroplating, electrolysis, and cathodic protection applications. With excellent durability and stability, our anodes can also be customized in various shapes and sizes to meet specific process needs.

The Pt/Ti anode is an insoluble anode composed of a titanium substrate coated with a thin layer of platinum. It combines high electrocatalytic activity with excellent corrosion resistance, making it a preferred choice in a variety of electrochemical applications.

Key Features:Specifications:

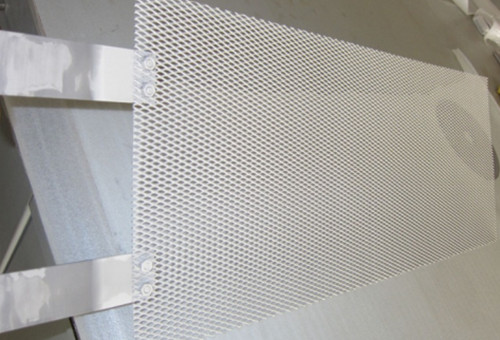

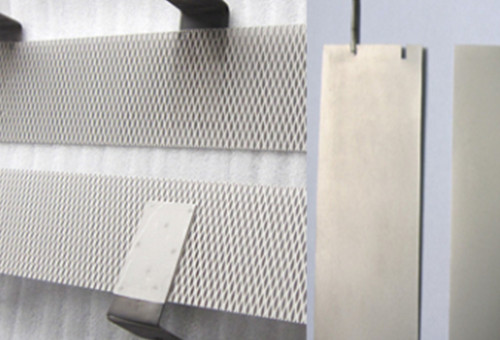

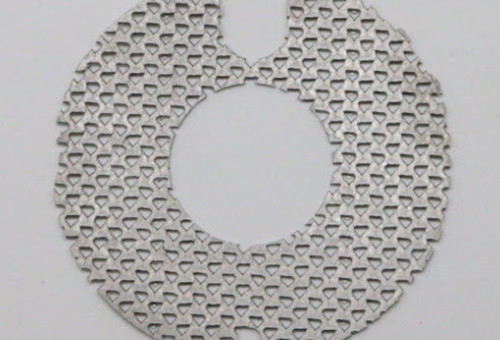

We also manufacture a variety of lead alloy anodes suitable for standard electroplating and specific electrolytic processes.

Our lead alloy anodes are made from special corrugated molds. The surface area of the lead alloy anode is increased by 45%, which reduces the voltage of the plating solution, increases the cathode current, and then reduces the current density of the anode, slowing down the loss of the anode and increasing the service life of the anode.

Contact us today for a quote, sample request, or technical consultation.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088