Grit Sizes:W0.25-50

Products Feature:High strength,Concentrated particle size distribution, low impurity content, good dispersibility and wear resistance

Recommended Uses:Grinding wheels with different bonds, diamond lapping pastes and diamond lapping compound

What is Synthetic Diamond Powder?

Synthetic Diamond Powder – General Type is a high-quality diamond material produced through high-pressure high-temperature (HPHT) synthesis. It offers excellent hardness, thermal conductivity, and wear resistance, making it ideal for general-purpose grinding, polishing, lapping, and precision finishing applications.

Features of Moresuperhard Diamond Powder

High hardness and wear resistance

Consistent particle shape and size distribution

Excellent thermal conductivity

Good self-sharpening properties

Cost-effective for a wide range of industrial applications

Classfications of Synthetic Diamond Powder

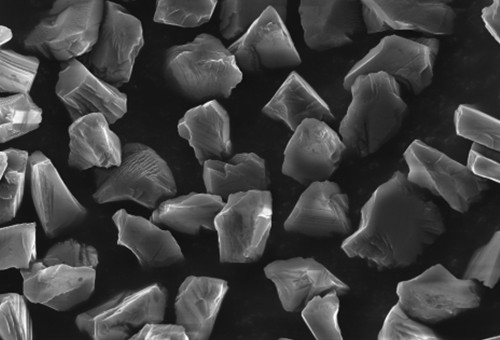

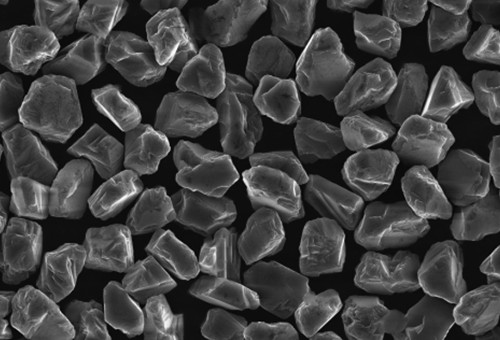

1.Wear-Resistant Type (SD-M1)

Using high-strength diamond raw materials, the product has regular and nearly spherical crystal shape, concentrated particle size distribution, high strength, strong grinding force, low impurity content, good dispersibility and wear resistance.

Recommended Uses:Metal bonds, ceramic bonds, electroplated diamond tools, diamond pastes and diamond polishing compound are used for cutting, grinding and polishing of electronic products, optical glass, precision ceramics, cemented carbide PCD/PCBN, gemstones and other materials.

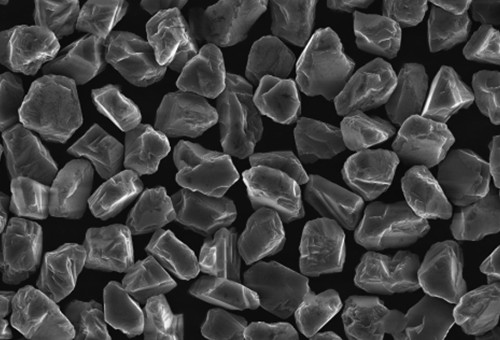

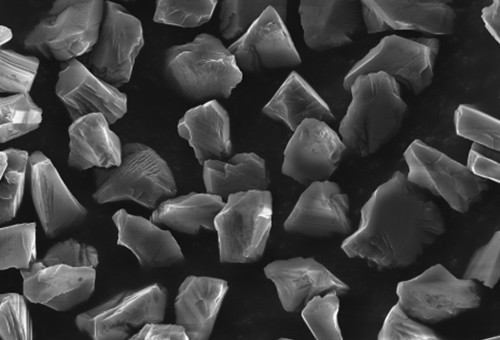

2.Sharp Type(SD-M2)

High-strength diamond raw materials are produced using special crushing, shaping, grading, and post-processing processes. The products have relatively concentrated particle size, regular crystal form, high strength, low content of impurities, and excellent sharpness and surface finish.

Recommended Uses: Resin bonds, ceramic bonds, metal bonds, electroplated diamond tools, diamond grinding pastes and grinding compound are used in the production processes of stone, glass, ceramics, dental materials, and hard gold processing; the products have relatively concentrated particle size, relatively regular crystal form, high strength, and are suitable for cutting, grinding, and polishing of miscellaneous materials.

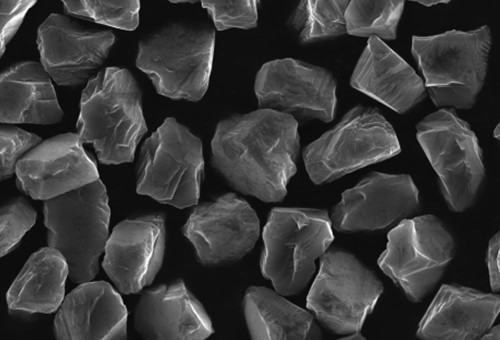

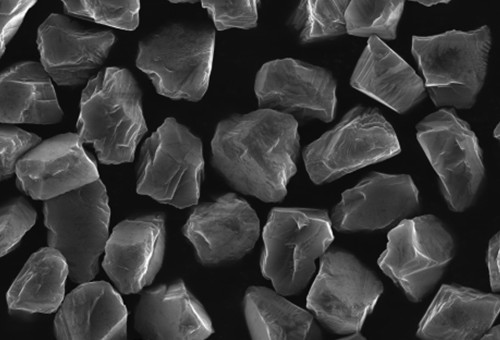

3.High Purity Type(SD-M3)

We use higher grade diamond raw materials with extremely low internal impurity content. After a special acid-base purification process, the metal ions and non-metallic ions on the surface of the diamond micropowder particles are removed, so that the impurity content is controlled at the PPM level, ensuring that the diamond micropowder particles have better fluidity, dispersibility and thermal stability.

Recommended Uses:It is recommended for the production of high-end PCD/PDC, electroplating and brazing diamond tools, metal bonding using higher grade diamond raw materials, extremely low internal impurity content, special acid compound diamond tools, mixed bond diamond tools.

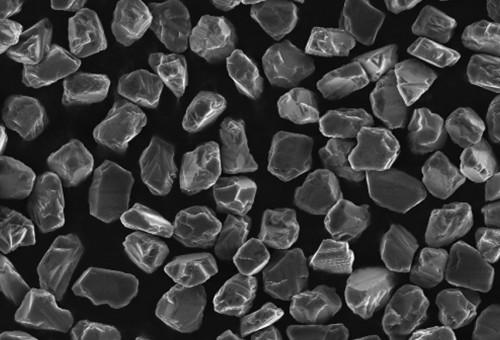

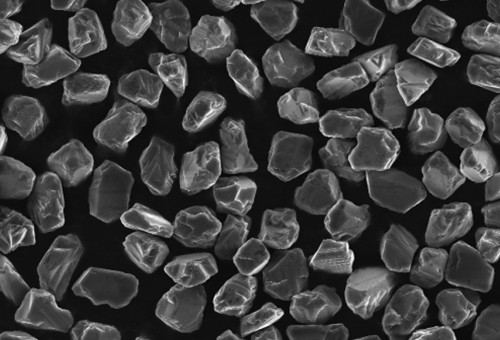

4.High Strength Type(SD-M4)

The raw materials are processed by high-strength diamond crushing, the micro powder has high strength, regular block crystal form, good thermal stability and long service life.

Recommended Uses:It is recommended for use in areas with special processing requirements such as precision ceramics, glass, sapphire, aerospace, 3C products, geological drilling, etc.

Diamond powder particle size table available

| Diamond Powder Grain Sizes | SD-M1 | SD-M2 | SD-M3 | SD-M4 |

| 0-0.25 |

√ |

√ |

√ |

√ |

| 0-0.5 |

√ |

√ |

√ |

√ |

| 0-1 |

√ |

√ |

√ |

√ |

| 1-2 |

√ |

√ |

√ |

√ |

| 2-4 |

√ |

√ |

√ |

√ |

| 3-6 |

√ |

√ |

√ |

√ |

|

4-8 |

√ |

√ |

√ |

√ |

| 5-10 |

√ |

√ |

√ |

√ |

| 6-12 |

√ |

√ |

√ |

√ |

| 7-14 |

√ |

√ |

√ |

√ |

| 8-12 |

√ |

√ |

√ |

√ |

| 8-16 |

√ |

√ |

√ |

√ |

| 10-20 |

√ |

√ |

√ |

√ |

| 15-25 |

√ |

√ |

√ |

√ |

| 20-30 |

√ |

√ |

√ |

√ |

| 22-36 |

√ |

√ |

√ |

√ |

| 30-40 |

√ |

√ |

√ |

√ |

| 20-40 |

√ |

√ |

√ |

√ |

| 36-45 |

√ |

√ |

√ |

√ |

| 40-50 |

√ |

√ |

√ |

√ |

| 40-60 |

√ |

√ |

√ |

√ |

Note: Other customized granularity can be provided according to the needs

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088