PCD Fiber Laser Cutting machine

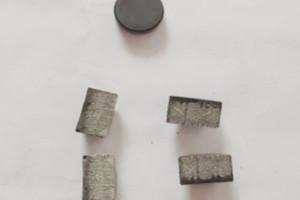

Cutting matrials :PCD Blanks and PCBN blanks

Charactericts: adjustment-free, maintenance-free and high stability,no need for a water cooler.

The power consumption of the whole machine is only 10% of the traditional laser cutting machine.

Maitenance Free Long services life High speed Laser cutting machine

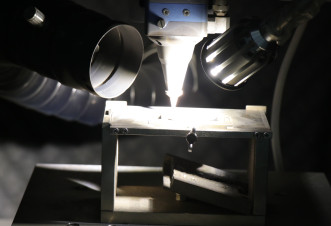

There is no optical lens in the resonant cavity of the laser of the precision diamond fiber laser cutting machine.which has the advantages of adjustment-free, maintenance-free and high stability. Because of the high photoelectricconversion rate of the fiberlaser, there is no need for a water cooler, The power consumption of the whole machine is only 10% of the traditional laser cutting machine, and the performance and stability ofthe equipment have been greatly improved.

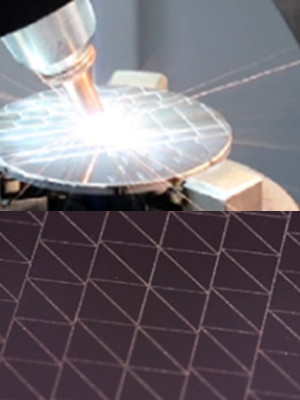

Laser cutting machines are widely used in the diamond industry. They can cut a variety of superhard materials with different thicknesses, such as cutting, punching, and pouring of PCD wire drawing dies, PCD composite sheets, CVD diamond, CBN composite sheets, ceramics, and silicon wafers etc.

Laser Cutting paraments

| laser power | low power | high power |

| 1.6 cutting speed | ≤100mm/min | ≥200mm/min |

| 2.0 cutting speed | ≤60mm/min | ≥140mm/min |

| 3.2 cutting speed | ≤10mm | ≤45mm |

| heat affected zone | ≤0.10mm | ≤0.10mm |

| maximum cutting thickness on one side | 2.5mm | 6.5mm |

| maximum cutting thickness on double side | 5mm | 13mm |

| table travel | 200mm*300mm | 200mm*300mm |

| maximum speed | 500mm/min | 500mm/min |

| rated power | 1000W | 2000W |

| physical dimension | 1610*1253*800 | |

Characteristic of Moresuperhard fiber laser cutting machine

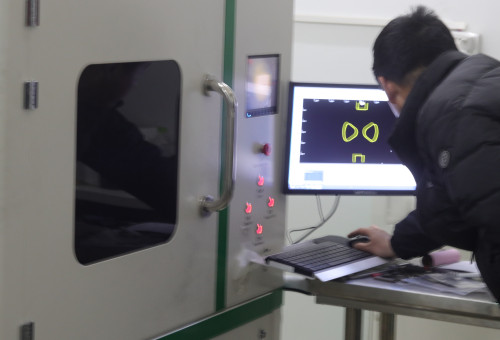

1.Originated from the production concept of precision machine tools,which is more stable, more precise and more durable. It integrates advanced cutting concepts and techniques, and the operation is more humanized.

2.The cutting kerf is thin, the loss of the material to be cut is small, the cutting speed is fast, and the use cost is low.

3.Two-dimensional graphics of any shape can be cut

Products Advantage:

1.Advanced and mature fiber laser head makes cutting smooth, stable and operation friendly.

2. No consuming parts, except protect lens.,No cooling tank,Easy maintenance.

3. Fiber laser photoelectric conversion rate is high, running power is only 1/10 of YAG laser type.

4.Moresuperhard pcd laser cutting machine are most powerful for cutting thick PCD up to 8mm at overall thickness at higher speed than YAG laser type. .

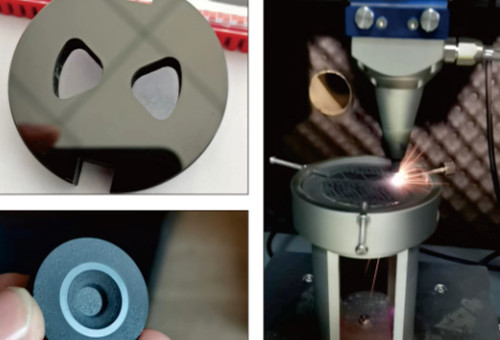

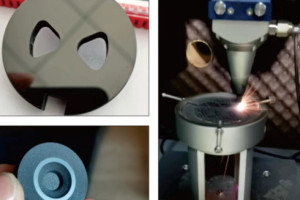

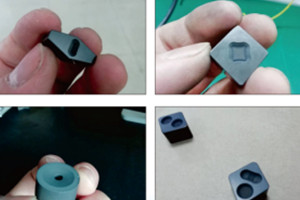

Finished product display after Laser cutting

Case of cutting PCD blanks

Customer's requirements:Fiber laser cutting PCD inserts and PCD compat sheet

laser cutting PCD turning tools

Laser Cutting Effect: the cutting surface is relatively smooth, and the diamond layer has no obvious burn marks and no obvious crack marks

Customers are very satisfied with the effect of laser cutting PCD

More details about PCD laser cutting machine

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088