Cutting

Home / Cutting / PCD Cutting Machine > PCD Fiber Laser Cutting Machine

PCD laser cutting machine is developed for super hard materials, mainly used for diamond, PCD composite sheet, PCBN, CBN, ceramics, CVD and other cutting and processing.And can process multi-blade grinding head, multi-blade milling cutter, drill bit, tooth cutter, special-shaped grinding head, PCD cutter, CBN cutter, PCBN cutter, etc. The finished products can be used in the processing of spherical cutter, ball milling cutter, forming cutter, chamfer cutter, round nose cutter, drill bit, tap and other super hard cutting tools.

The principle of laser cutting PCD is that a laser beam with extremely high energy density irradiate the surface of polycrystalline diamond, and part of the light energy is absorbed by the surface and converted into heat energy. The local temperature of the irradiation spot rises rapidly to tens of thousands of degrees, which makes the polycrystalline diamond material melt or even vaporize locally and form pits.

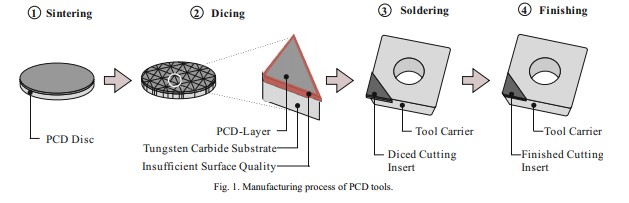

The manufacturing process of PCD tool is described in the following figure:

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088