Cutting

Home / Cutting / Tool Blanks > Single Crystal Diamond Die Blanks

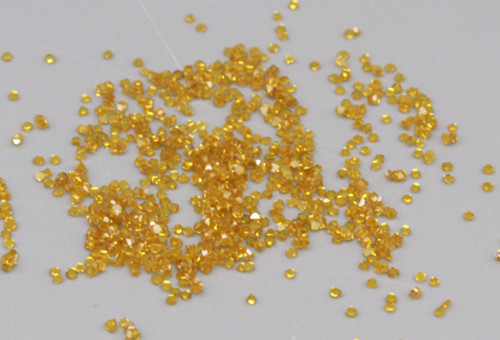

Diamond Type:CVD diamond and MCD diamond(HPHT diamond)

Crystal Orientation:111

Thickness:0.5mm-2.59mm

Purity:Medium nitrogen content, specially used for wire drawing dies

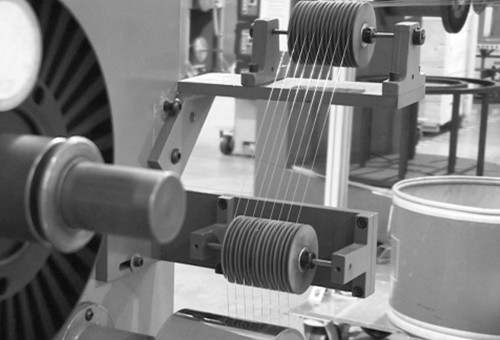

Single crystal diamond (SCD) drawing die blanks are engineered for ultra-fine wire drawing applications. These blanks provide uniform texture, excellent wear resistance, high smoothness, and superior precision. They offer significantly extended tool life while maintaining consistent wire surface quality and dimensional accuracy.

| Material | Type Ib synthetic single crystal diamond |

| Diameter Range | 0.6 – 1.8 mm |

| Purity | Ultra-pure, no visible inclusions |

| Drawing Area | 50% larger than previous-generation blanks |

| Failure Rate | Less than 0.1% |

| Property | SCD | PCD |

|---|---|---|

| Wire Diameter Capability | Down to 0.02 mm | > 0.08 mm |

| Surface Finish | Mirror-like, ultra-smooth | Moderate |

| Die Life | 30-50% longer | Standard |

| Thermal Conductivity | Excellent | Moderate |

| Precision | High | Lower |

| Material | Wire Diameter | Old SCD Life | New SCD Life | Improvement |

|---|---|---|---|---|

| Stainless Steel | 0.06–0.10 mm | 10–12 kg | 22–25 kg | +90–100% |

| Ni-coated Alloy (Medical) | Fine wire | 38 kg | 56 kg | +47% |

| Carbon Steel | 0.012–0.20 mm | — | +30–40% | — |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088