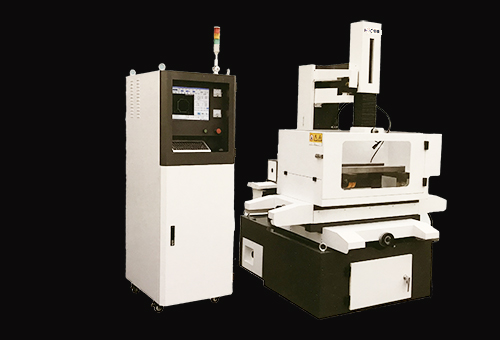

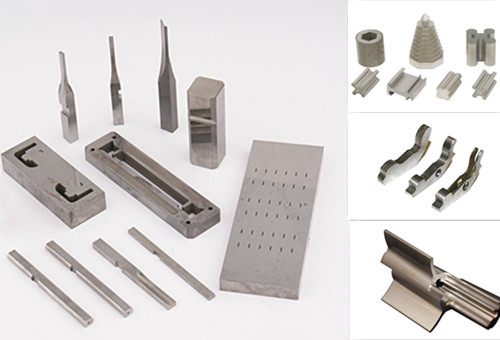

wire cut EDM machines which are widely used in the fields of moulds, automobile parts, aeronautics and astronautics, electronic instrument, military, light industry, and household appliance

Wire Cut EDM, also known as (wire electrical discharge machining or wire EDM) is a high-precision method for cutting nearly any electrically conductive material. A thin, electrically-charged EDM wire held between upper and lower mechanical guides forms one electrode, while the material being cut forms the second electrode. Electrical discharge between the wire and the workpiece creates sparks that rapidly cut away materials.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088