Materials:CVD diamond ,natural diamond

Classfactions:single point diamond dressing tools,multi-point diamond dresser,forming diamond dresser

Specifications: customized according to drawings

Applications:Truing and dressing grinding wheel including general grinding wheel and super abrasives grinding wheel

The grinding wheel dressing process is an important part of the grinding process. The main purpose is to remove passivated abrasive particles, improve the sharpness of the grinding wheel, improve the concentricity or shape the profile of the grinding wheel.

Moresuperhard diamond dressing tools are mainly used for semi-fine grinding and finishing dressing of CNC grinding machines, ordinary cylindrical grinding machines, centerless grinding machines, and surface grinding machines. High-quality strip-shaped diamond is used as raw material. There is no need for sharpening and repairing during use, and the diamond can be completely consumed. The self-owned surface polishing technology makes the polished diamond have excellent smoothness and extremely low friction coefficient, and has excellent chip resistance. , The surface roughness of the processed workpiece is close to the processing effect of natural diamond.

Mainly Three Types Of Diamond Dressing Tools

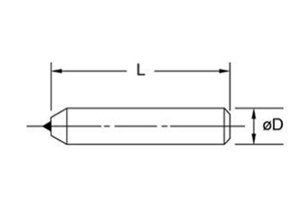

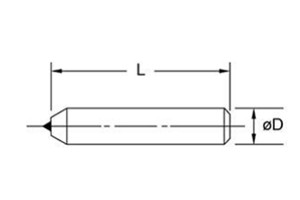

Single point diamond dressers

Application:dressing straight type conventional abrasive wheels. Dressing ceramic abrasive SG grinding wheels ,simple profiles, thread and gear grinding

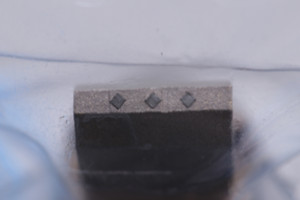

Multi-point diamond dressing tools

| Number of Diamonds | Applicable Wheel Diameter (mm) | Application |

|---|---|---|

| 3 | Φ200–Φ400 |

Truing of surface for centerless and cylindrical grinding wheels |

| 5 | Φ400–Φ600 | |

| 7 | Φ500–Φ750 | |

| 9 | Φ750–Φ900 | |

| 12 | Φ900–Φ1100 |

Non-standard size products can be customized according to customer needs

Application: large OD wheels, surface and centerless grinding wheels.It is used for auto parts, mould industry,and other precision machinery parts industry

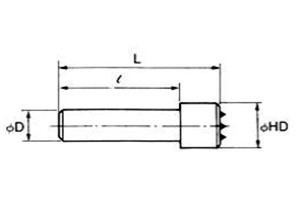

Forming diamond dressers

Application: dressing specific forms into conventional abrasive wheels(formingarc, angle, groove radius and other complex profiles) .

Two types of forming diamond dressers: chisel type and cone type.

| Diamond Weight | Diamond Type | Diamond Grade | Suitable Wheel Grit | Diamond Angle | Diamond Radius |

|---|---|---|---|---|---|

| 0.8 ct | Natural / Synthetic | Grade A / B | 60–80# | — | R0.05 |

| 1.0 ct | Natural / Synthetic | Grade A / B | 60–100# | — | R0.1 |

| 1.25 ct | Natural / Synthetic | Grade A / B | 60–100# | 40° | R0.15 |

| 0.8 ct | Natural Diamond | Grade A / B | 80–220# | 55° | R0.2 |

| 1.0 ct | Natural Diamond | Grade A / B | 60–300# | 60° | R0.3 |

| 1.2 ct | Natural Diamond | Grade A / B | 80–500# | 70° | R0.5 / R0.8 / R1.0 |

Non-standard size products can be customized according to customer needs

Characteristic

1.The diamond wears evenly and does not need to be sharpened. It is suitable for dressing all kinds of conventional abrasive wheels.

2.Allows higher individual feed rates and exhibits longer service life.

Diamond dressing tools using tips

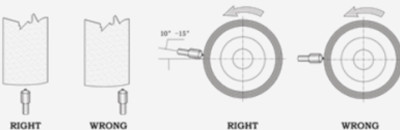

Diamond dressor is generally used for dressing traditional grinding wheels. When using, we should pay attention to that the dressor and grinding wheel keep an Angle of 10 to 15 degrees, while the grinding wheel keep counterclockwise rotation.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088