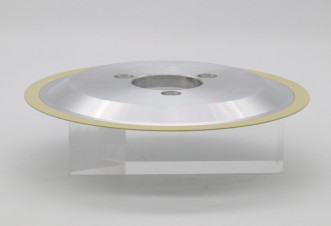

►Model: 3A1

► Dressing high precision diamond roller

► Bond: vitrified bond

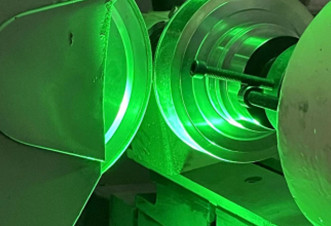

► Applicable grinding machines: WAIDA, WASINO, PROFILTEC, PETEWE, DOEBLI, etc.

► Abrasive layer thickness up to 1mm

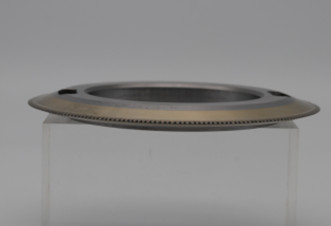

Used for high-precision electroplated diamond/CBN grinding wheel, electroplated diamond roller, etc.

Moresuperhard provides customized ceramic optical profile grinding wheels for dressing high-precision diamond rollers. Electroplated/sintered diamond rotary dresser need to undergo repeated grinding and testing on the grinding machine during the production process to maintain the corresponding size and precision. The vitrified diamond grinding wheel has the advantages of less wear and tear when dressing high-precision rollers, maintaining good shape accuracy, ensuring small linearity errors of the profile generatrix, reducing grinding burns, reducing surface roughness, and prolonging the service life of the rollers.

Application fields of vitrified diamond optical profile grinding wheel

Vitrified diamond optical profile grinding wheel is used for grinding and dressing of high-precision electroplated diamond/CBN grinding wheels, electroplated diamond rollers, diamond sintered rollers, PCD/CBN/MCD tools, diamond grinding wheels, wear-resistant parts and various diamond tools.

Supporting special grinding machines: WAIDA, WASINO, PROFILTEC, PETEWE, DOEBLI, etc.

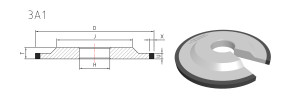

Specification of optical profile grinding wheel

| Model | D(mm) | H(mm) | T | U | X | Grit |

| 3A1 |

125 150 200 |

22 31.75 |

10 |

1 1.2 1.5 2 |

5 10 |

#200~ |

| Other specifications and sizes can be customized according to drawings | ||||||

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088