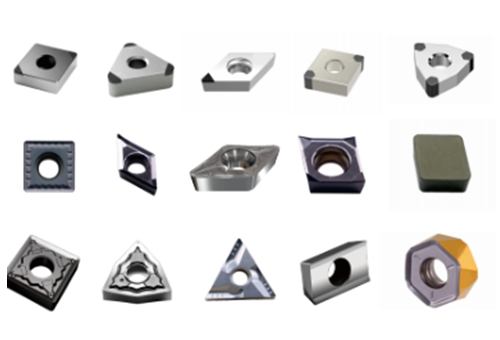

Peripheral Grinding PCD/PCBN Indexable Inserts

Minimum inscribed circle:3.96mm

Maximum outer circle:40mm

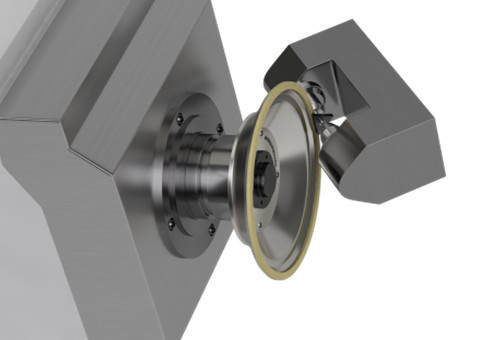

Double-sided chamfering of cutting tools can be machined in a single clamping.

Grinding Wheel Diameter:400mm

The CNC peripheral grinding machine is specially designed for precision grinding of PCD and CBN indexable inserts. With high rigidity and advanced control technology, it ensures exceptional dimensional accuracy and consistent edge quality. The machine supports automatic clamping, tool positioning, and multi-axis interpolation, achieving efficient and stable grinding performance.

1.Efficient and convenient programming software

Innovative research and development of non-standard blade grinding function,targeting complex curves, involute and other grinding needs, with one click import of drawings to complete processing settings.

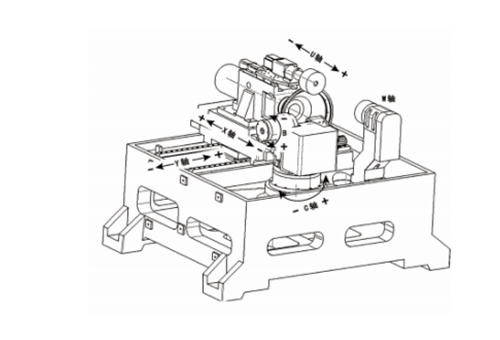

| Minimum inscribed circle | 3.96mm | Y-axis repeat positioning accuracy | 0.001mm |

| Maximum outer circle | 40mm | B-axis rotatiom angle range | 0-360° |

| Grinding wheel diameter | 400mm | Maximum rotation speed of B-axis | 90°/S |

| Maximum spindle speed | 2000r/min | B-axis positioning accuracy | 0.005° |

| Spindle motor power | 7.5/12.5kW | B-axis repeat positioning accuracy | 0.002° |

| X-aixs travel | 160mm | C-axis rotation range | -90°-+90° |

| Maximum moving speed of X-axis | 10000mm/min | Maximum rotation speed of C-axis | 150°/S |

| X-axis positioning accuracy | 0.002mm | C-axis positioning accuracy | 0.005° |

| X-axis repeat positioning accuracy | 0.001mm | Maximum clamping thickness | 25mm |

| Travel Y-axis | 580mm | Clamping pressure | 500-8800N |

| Maximum Y-axis movement speed | 10000mm/min | Machine weight | 6000kg |

| Y-axis positioning accuracy | 0.002mm | Dimension | 2950*1850*2400mm |

Moresuperhard also offers matching ceramic diamond peripheral grinding wheels. Please inquire for more information.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088