Grinding

Home / Grinding / PCD Grinding Machine > Diamond Bruting Machine

Development of a high quality, high yield bruting machine for all types of diamond goods.

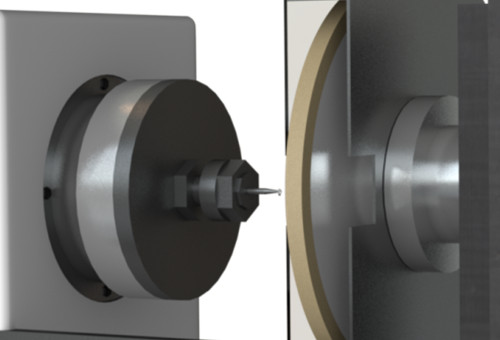

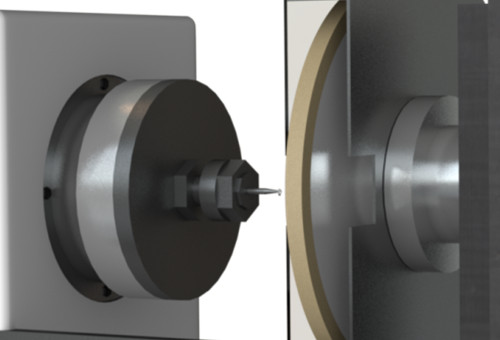

Dual operations mode:automatic feeding and manual grinding

Applications:0.1carat-50carat diamond bruting and regrinding

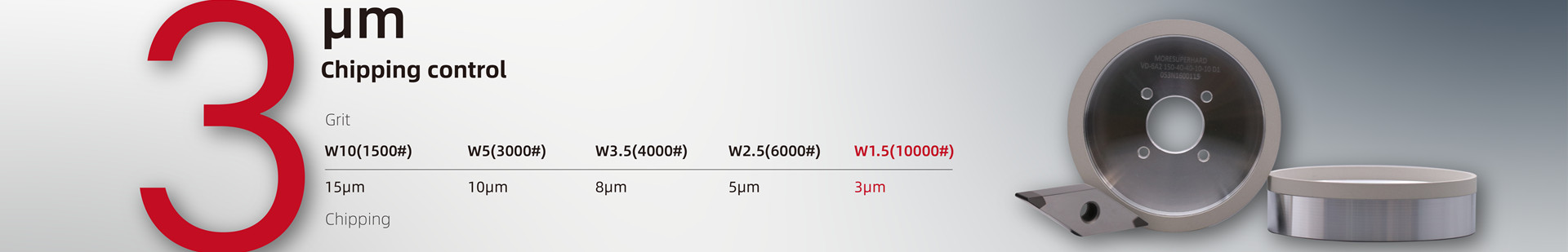

Matching grinding tools:D170mm 1A1 vitrified diamond bruting wheel

The Diamond Bruting Machine is designed for precise and efficient bruting of diamonds. It supports both automatic and manual grinding modes, delivering outstanding processing accuracy and surface quality for diamonds ranging from 1 point up to 50 carats.

Dual Operation Modes

Automatic feeding and grinding Manual grinding mode

High-Precision Processing

Feed pressure: 1 μm

Processing accuracy: ≤ 0.02 mm

Optimized Grinding Control

Center amplitude adjustment: 0–12

Swing amplitude: 0–24

Swing speed: 0–15

Grinding wheel spindle speed: 900–1800 RPM

Diamond spindle speed: 800–1700 RPM

Stable Cooling System

Efficient water cooling to maintain consistent performance

Integrated Lighting: Built-in 12V LED light source for clear and precise operation Technical Specifications

| Items | Specifications |

| Grinding Wheel Sizes | 170*32*10*12mm |

| Stone Sizes Range | 1points-50carats |

| Processing Accuracy | ≤0.02mm |

| Feed Pressure | 1μm |

| Cutting Method | Outer round cutting(for round brilliant cuts) |

| Cooling Method | Water Cooling |

| Lighting Built-in | 12V LED |

Precision bruting of diamonds for round brilliant cuts

High-accuracy edge shaping and repair work

Suitable for diamonds of various sizes and stress levels

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088