Precision Tools for Fancy Diamond Settings

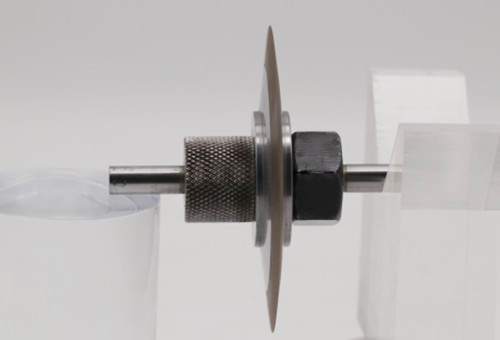

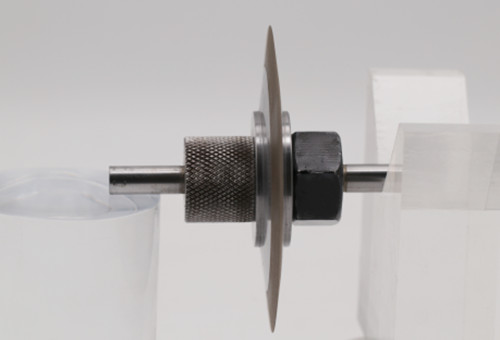

Bond:Metal Bond

Abrasives:Diamond Abrasives

Diameter:90mm

Angles: 10° to 180°

Knurled and smooth shafts available

Our Diamond Grooving Wheels are designed for precise cutting, shaping, and polishing of diamonds, gemstones, and colorstones. Perfect for various diamond setting techniques, such as Pie Cut Setting, Illusion Setting, and Invisible Setting, these wheels deliver consistent quality and outstanding performance. With a focus on durability and precision, our grooving wheels ensure flawless results for all types of fancy diamonds.

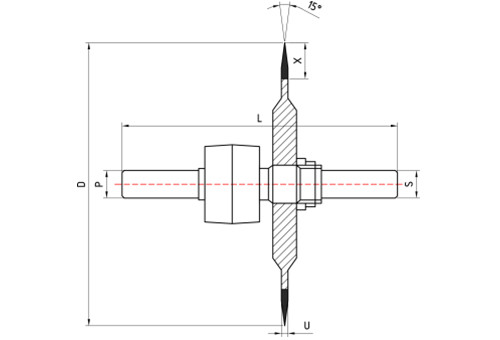

| D(mm) | U(mm) | X(mm) | V(˚) | P(mm) | L(mm) | S(mm) |

|---|---|---|---|---|---|---|

| Ø90 | 1 to 8 | 10 | 45° to 180° (in gap of 5°) | 25.6 | 90 | 8.6 |

Available Angles: 10°, 15°, 20°

Perfect for Invisible Setting, these wheels are specifically designed for princess-cut diamonds, creating precise grooves for an elegant and secure setting.

Available Angles: 10° and 15°

Ideal for grooving colored gemstones, these wheels allow for detailed, high-quality settings that preserve the natural beauty of the stones.

Available Angles: 40° to 180° (in gap of 5°)

Specially designed for heart-shaped diamonds, these wheels enable precise cuts, enhancing the beauty of the stone while maintaining perfect groove angles for any custom setting.

For more information on our Diamond Grooving Wheels or to place an order, please reach out to us today. Our team is here to help you select the best tools for your diamond cutting and setting needs.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088