Customized diamond grinding

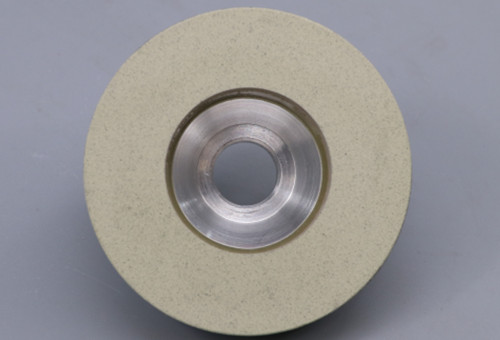

Moresuperhard provide spicific vitrified diamond grinding wheel for grinding diamond scribing wheel

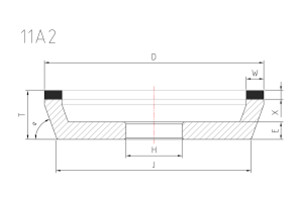

Specifications:11A2 D50*H10*T25*W12*X10 1000#

Characteristic:high efficient,high precision and long service life

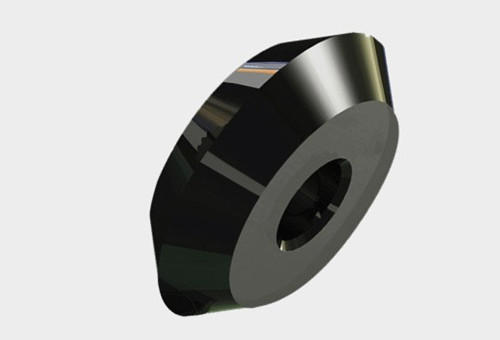

what is diamond scribing wheel?

The diamond cutter wheel for glass cutting is mainly suitable for high-precision and high-quality cutting of liquid crystal glass in the electronics industry. It can also cut architectural and automotive glass. It is an ideal substitute for ordinary glass cutters and hard alloy glass cutter wheels.

Moresuperhard provide customized diamond grinding wheel for grinding pcd cutting wheel for glass.

Specifications of vitrifed diamond grinding wheel

11A2 D50*H10*T25*W12*X10 1000#

Vitrified diamond grinding wheel advantages

1.Customized formula, more suitable for grinding diamond glass cutter wheel

2.Through the grinding tests of many customers, the quality is reliable and guaranteed

3.Vitrifed diamond grinding wheel has good shape retention and can achieve high precision grinding

4.Vitrified diamond grinding wheel has good self-sharpening, long dressing interval and easy dressing

Moresuperhard have rich experiences in grinding PCD diamond workpieces.Moresuperhard provide customized diamond grinding wheel for you according to your grinding machine and worpieces.

Moresuperhard also provide diamond grinding wheel dressing solutions.

Please contact us freely.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088