Grinding

Home / Grinding / PCD Grinding Machine > Light 5X PCD Laser Machining Center

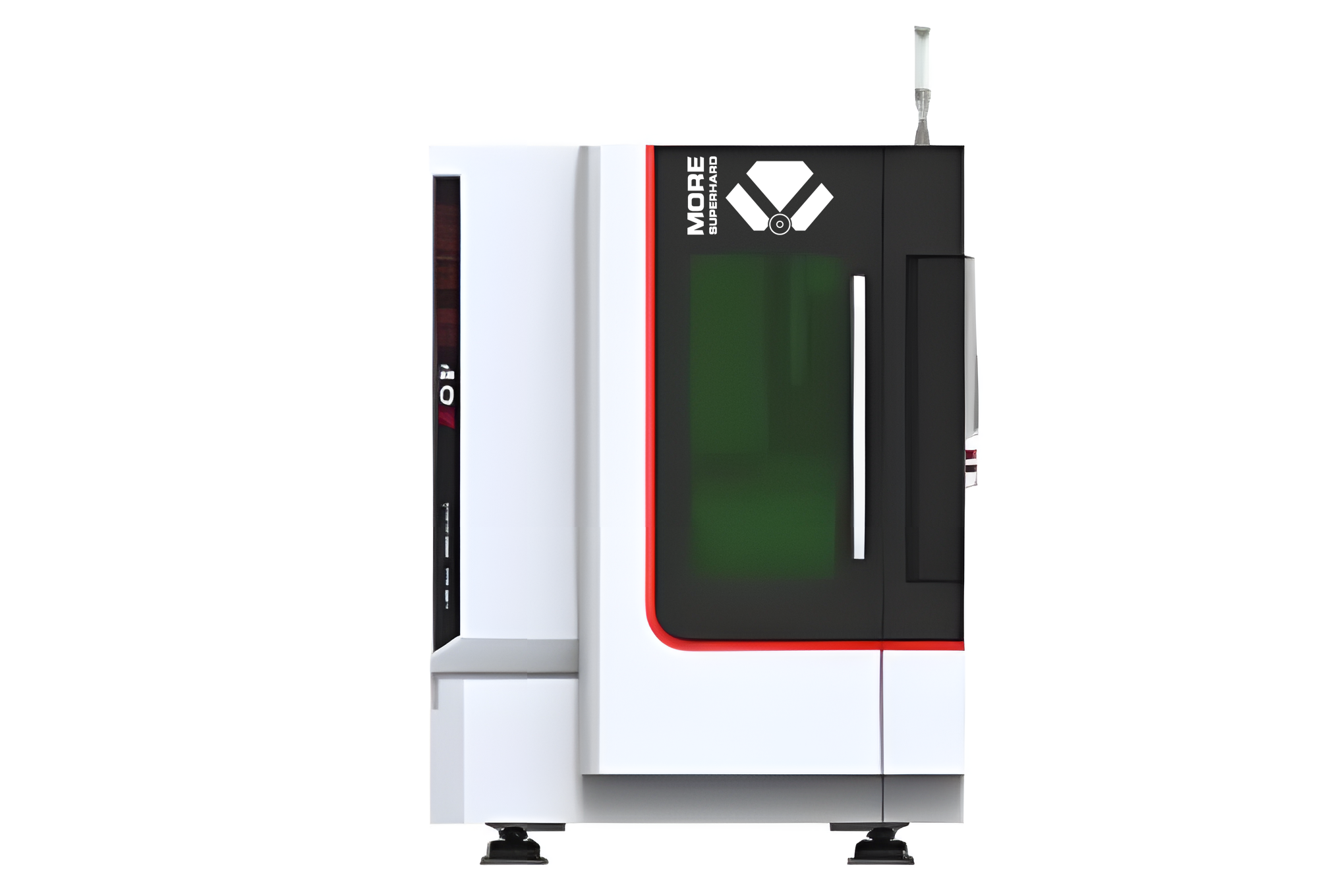

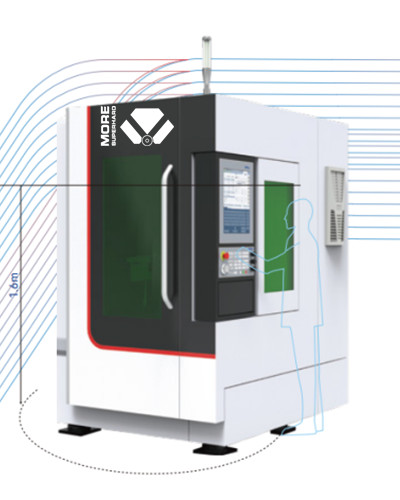

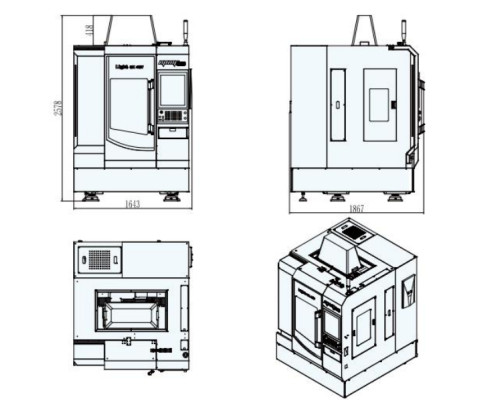

Fiber Laser Grinding Machine for 3C PCD cutting tools

Application:Laser machining PCD reamers,PCD drills and various PCD formin tools

Currently, it is widely used in processing PCD, CBN, cemented carbide, ceramics, metals and other materials.

Features:Flexible solutions can be developed,Complete all processing of 3C tools in one clamping

Features of Moresuperhard 5X PCD laser machining center

1.Unique features: flexible solutions

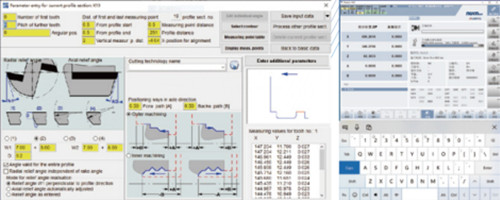

Based on the customer's personalized samples, we can develop flexible solutions to solve customer pain points. Solutions to customer pain points can be achieved through ultrafast laser process parameter settings, multi-axis linkage coordination and GTR software.

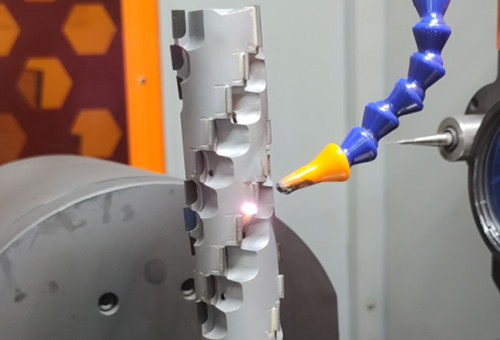

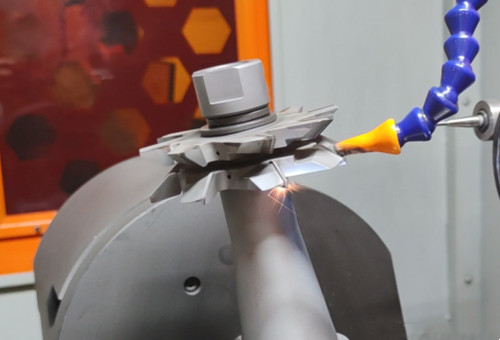

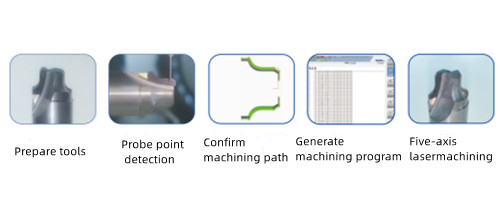

2.Simplified machining process: complete machining process in one clamping

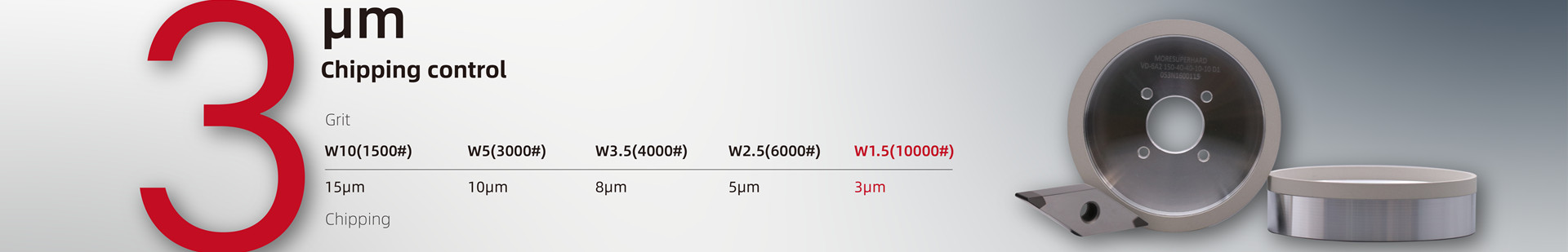

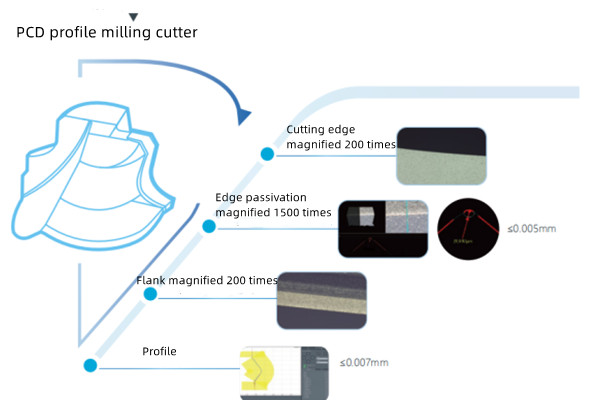

Chip breaker processing

Five-axis laser processing is used to improve the processing accuracy of the workpiece and extend the tool life. The ribbon-shaped and spiral chips can effectively control the chip debris,so that it can be discharged smoothly out of the hole without damaging the surface finish of the inner hole, and improve the product qualification rate.

Wide processing range

3.Fully digital integrated processing technology

One clamping can complete the rough and fine machining of the workpiece, and can achieve high-speed and high-precision machining of complex parts.

4.Highly intelligent: fully compatible with GTR software

High-precision control

| category | items | unit | parameter |

| stroke | X,Y,Z axis | mm | 400*250*300 |

| C workbench size | mm |

Φ100 |

|

| Accuracy |

Positioning accuracy (X/Y/Z) Accuracy Positioning accuracy (B/C) Repeat positioning accuracy(X/Y/Z) Repeat positioning accuracy(B/C) |

mm '' mm '' |

0.005 10 0.003 5 |

| Processing Range |

Maximum tool diameter x length x weight Workpieces calmping interfance |

mm/kg mm |

Φ100*200*8 HSKA63 manual |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088