Grinding

Home / Grinding / PCD Grinding Machine > PCD saw blade EDM Grinding Machine

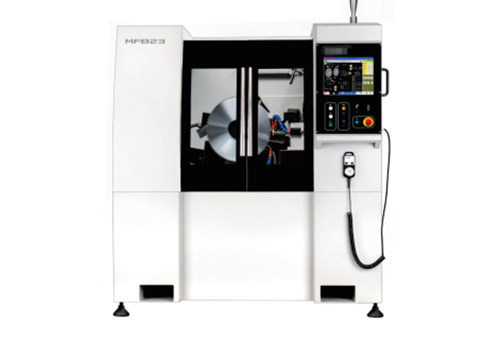

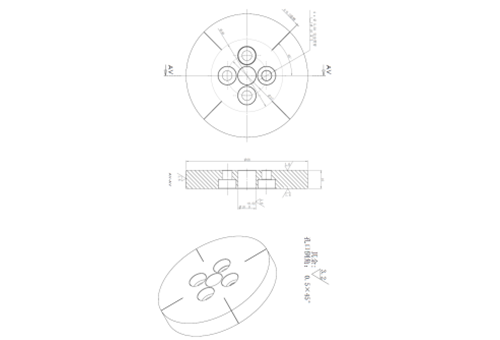

Model:MX813,MF823

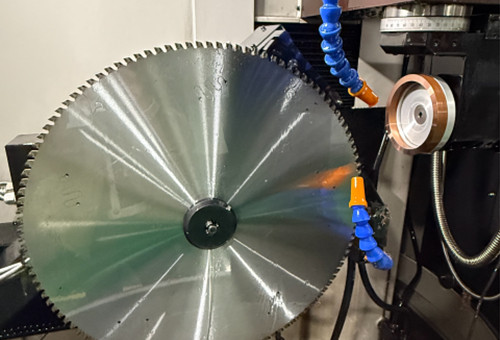

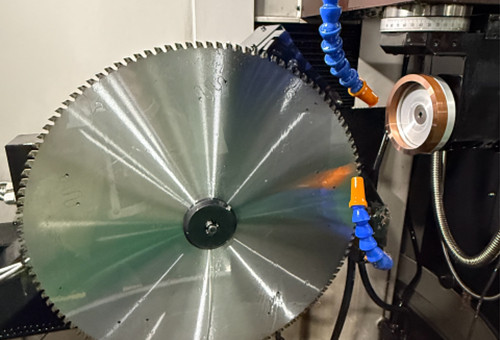

Applications:Grinding and Regrinding PCD Saw Blades

Machinable Diameter:80mm-820mm

Multi-axis CNC

Stepless speed-regulating grinding head

Servo tooth-shifting mechanism

★MX813 and MF823 are dedicated saw blade processing machines. They are two machines with unique design concepts for PCD saw blade grinding and regrinding.

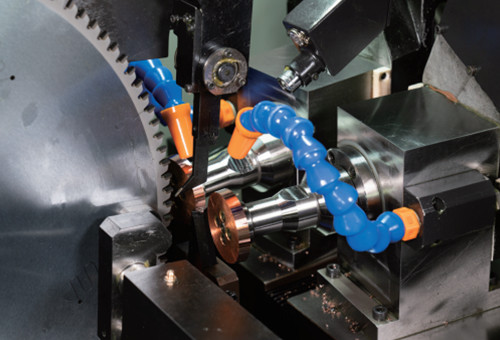

★The machine tool adopts multi-axis numerical control, stepless speed regulation grinding head and servo gear shifting mechanism, which can realize the electrical discharge processing of PCD circular saw blades with various tooth shapes.

★The MX813 and MF823 PCD saw blade electrical discharge grinding machine is mainly designed for grinding the top, chamfering and double-sided grinding of various conventional saw blades with diameters ranging from 110 to 800mm and tooth spacing ≤70mm.(If OD<110mm need to change a fixture.)

●The servo gear pulling method that uses lead screw drive guide rail positioning and interpolation to achieve circular positioning significantly highlights the rigidity of the lead screw guide rail gear pulling, and controls the positioning accuracy of the 800mm diameter saw blade gear pulling within 0.01mm.

●The slide table adopts an automatic control system and supports the automatic and precise positioning function when different specifications of saw blades are replaced. The entire operation process does not require manual intervention. Through intelligent control, the operation procedures are standardized and simplified, effectively enhancing the convenience of equipment use.

●The dual-filtration system design not only ensures reliable filtration in the oil circulation system but also guarantees stable oil supply pressure in the oil flushing system.

●The professionally developed PCD processing pulse power supply has been significantly enhanced

●While enhancing processing efficiency, it effectively ensures the quality of cutting edge processing.

●It is equipped with a dual-sensor automatic fire extinguisher system and adopts an independent power supply device. When an unexpected fire occurs on the machine tool, this system can automatically start up with independent power supply support to ensure the orderly execution of fire extinguishing operations.

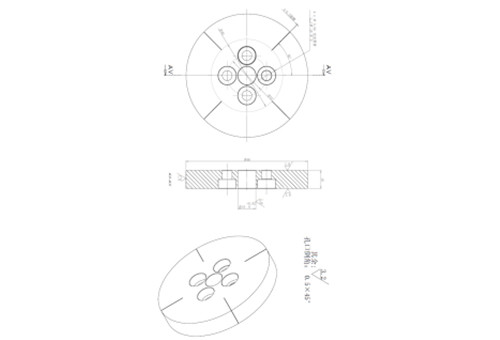

●It has two clamping methods: center clamping and tooth root clamping, and they can be interchanged. To meet the market's different precision detection requirements for double-sided saw blades, the corresponding detection standards can be achieved by interchanging the fixtures.

●The single-sided sliding door design effectively increases the operating space and enhances the operation convenience and practicality.

●The genuine Windows 7 operating system and self-developed control system have a simple and easy-to-operate interface. The powerful memory and interface configuration provide a good platform for continuous improvement in the future.

MX813 PCD Saw Blade Electric Spark Grinding Machine is an excellent machine with unique design ideas , taking use of seven-axis CNC and swivel head design to achieve spark erosion CNC grinding on the top of the PCD circular saw web. This machine tool adopts concentric circular dial tooth indexing technology to reduce the process of individual tooth checking indexing, shorten non-machining time, and improve machining accuracy. And it uses central positioning clamping to achieve the same clamping method for saw blade grinding and field use, improving the actual use effect of the saw blade. The machine is equipped with online turning of the discharge electrode forming the capacity of online compensation and high precision of processing, which could provide more value for customers.

Appearance

1) The compact design is a kind of space saving type, which could effectively take use of the ground floor area, and easy to debug.

2) The color LCD touch screen with advanced operation concept and convenient to make touch operation.

3) The big window takes use of the sliding door structure for a sweeping view of the grinding process and the whole work area at any time.

4) The whole-round protection to avoid noise, splash and radiation effectively and maintain more stable operation.

5) The strong and stable mechanical structure can realize a vibration free operation of the MX813, which is helpful to improve the quality of the cutting edge.

6) The perfect separation. The external electrical layout, electrical, mechanical and working areas are separated from each other with multi pole insulation and multi-layer protection which simplify the maintenance and improve the service life of the machine.

Mechanical

1) The high power precision grinding head with high rigidity and high accuracy, the Casted machine body with good stability;

2) Seven CNC axis with double grinding heads design, providing a highest machining flexibility and extending the freedom of processing degrees, which could complete the challenging grinding task quickly and accurately and bring the perfect grinding effect.

3) It is equipped with a numerically controlled interlocking gear shifting mechanism, enabling the grinding of each tooth after it is shifted to the designated positione.

4) The saw blade clamping adopts a reducer sleeve, which is simple and cost-effective.

5) The application equipped with a manual slide table greatly expands the application space of the machine tool. It can process both small and large saw blades, meeting the grinding requirements of customers to the greatest extent.

6) The professionally designed electrode wheel realizes the function of cutting off during the turning process, avoiding the short circuit caused by the entanglement of copper chips during the turning process.

7) It is equipped with a air pressure alarm system. Ensure the stability of the processing procedure.

8) The high-rigidity structural design provides long-term stability and high precision for the machine tool.

9) The working circulation system adopts a high-efficiency and low-noise centrifugal pump, which can quickly supply, drain and flush oil.

10) External fuel tank design. The enlarged fuel tank design ensures the oil output of the oil pump. Two sets of flushing oil pipes supply oil, making the processing more stable and reducing the possibility of fire.

11) The CNC transmission system is composed of NIDEC AC servo motors, stepper motors, precision ball screws and precision linear guides, ensuring precise positioning.

12) Advanced functional components and precision assembly technology ensure the motion accuracy of the machine tool.

13) System automatic lubricating oil circuit - automatically lubricates the guide rails and lead screws of the equipment, effectively ensuring the normal operation of machinery, maintaining precision, and extending the service life of the machine tool.

Control Systems and Software

1)Seven CNC axis for swing discharge and perfect grinding.

2) Upgraded drive technology to ensure a strong power and shorten the processing time

3) Equipped with electronic hand wheel simple and convenient in operation which makes the machine quickly into the working station

4) The adaptive-adjustment of the empty running speed and the processing speed reduce the non-production time and ensure a shortest processing time

5) Forward and backward in a fast speed to ensure an accurate and reliable positioning

6) The humanized design with simply icon and filling- in type to ensure a more convenient and quick operation

7) Simple in operation. It is required to input data in the operation panel to complete programming.

8) Real-time fault alarm

9) Save/restore function for the processing power, easy to use

Application

1) Rich processing expert database and mature processing strategy. The rich Apex tooth shape library has the expansion ability, simple in grinding and reduces the operation difficulty to the utmost, together with the side edge processing ability.

2) The automatic electrode function during the machine processing, and automatic compensation after the turning is completed thus to avoid non-accuracy of the machine processing due to the electrode loss.

3) The CNC gear shifting technology to reduce the non processing time significantly and improve the degree of accuracy

4)There is no need to adjust the distance between the gear and the depth of the base

5) The tooth processing in a cycle could be interrupted

6) Once fitting and once forming

7) Lower cost of building saw blade production lines

8) To take use of the copper electrode wheel for cost-saving

9) The processing depth could be settled due to requirements. The electrode wheel could automatically adjust the speed and steering according to the requirements.

10) The implementation of regular skip tooth machining greatly expands the variety of saw blades to be machined.

11) Add voltage detection function. When the machine tool has a pulse power failure, the operator can judge by himself according to the display to improve the safety factor.

12) Regardless of the power outage of the machine tool during a certain working period, it can directly process the current tooth shape when the machine tool is turned on again, with minimal impact on machining accuracy.

13) The improvement of pulse power supply leads to absolute improvement of machining efficiency, delamination of the tool head, and burned layer of the edge.

Environment Requirements

1)It is required to ensure ground wire reliable grounding.

2) The connection requirements of the main power: MX813 requires a three phase and four line system power connected under 380 volt, with a value difference range of +10%~-5%, while the sudden voltage change is not allowed which could also not be a common power supply for other electrical equipments with high voltage, or the user shall prepare voltage regulator, otherwise the consequences will be vain. In addition, it is required to take protection measures such as installing the air switches on the front of main power for the machine.

3)Connection requirements for gas path: the gas path of the MX813 machine requires inlet pressured dry and clean air of 0.6~0.8MPa.

4)Air must be clean without dust. There is no quake source near the machine. If any, it is required to install the machine on the foundation with anti-earthquake ditch.

There is no dust source such as and grinding machine to ensure the air out of grinding particles. There is no chemical corrosive element indoor (far off the chemical lab, surface heating treatment workshop and etc). It is required to avoid higher humidity(with relative humidity among 40~60%).

—Inside temperature Conditions: Guaranteed precision 20±3℃ Guaranteed Working 15~30℃

MF823 EDM Double Sides Grinding Machine is an excellent machine with unique design ideas, taking use of six-axis CNC and double grinding head design to achieve spark erosion CNC grinding on double sides of the PCD circular saw web. It can also be single-sided grinding and two-axis alternately grinding. Using CNC Dial Tooth Indexing Technique, the machine reduces the progress to make separate tooth checking and indexing, shortening the processed period, enhancing the precision. The machine is equipped with online turning of the discharge electrode forming the capacity of online compensation and high precision of processing, which could provide more value for customers.

Appearance

1) The compact design is a kind of space saving type, which could effectively take use of the ground floor area, and easy to debug.

2) The color LCD touch screen with advanced operation concept and convenient to make touch operation.

3) The big window takes use of the sliding door structure for a sweeping view of the grinding process and the whole work area at any time.

4) The whole-round protection to avoid noise, splash and radiation effectively and maintain more stable operation.

5) The strong and stable mechanical structure can realize a vibration free operation of the MF823, which is helpful to improve the quality of the cutting edge.

6) The perfect separation. The external electrical layout, electrical, mechanical and working areas are separated from each other with multi pole insulation and multi-layer protection which simplify the maintenance and improve the service life of the machine.

Mechanical

1) The high-power precision grinding head with high rigidity and high accuracy, the Casted machine body with good stability;

2) Seven CNC axis with double grinding heads design, providing a highest machining flexibility and extending the freedom of processing degrees, which could complete the challenging grinding task quickly and accurately and bring the perfect grinding effect.

3) Equipped with CNC+ dialing mechanism to achieve dial the gear tooth by tooth in place and then to place the discharge grinding.

4) Equipped with a pneumatic pressing foot to achieve a stable processing of the saw blade, avoiding the symmetrical deviation caused by the beating of the base plate.

5) The saw blade clamping takes use of the adjustable set, which is simple with low cost.

6) Equipped with a manual sliding table for a larger application space of the manual sliding table which could process both small blade and large saw blade to satisfy the grinding requirements of the customer to the utmost.

7) Equipped with a professional designed electrode wheel to realize the cutting function during the turning process to avoid the copper scrap winding caused by short circuit during the turning process.

8) Equipped with the air pressure system to ensure the stability of the machine processing.

9) The high rigid structure design provides the machine with a long-term stability and high precision.

10) The working circulation filter system takes use of a high efficient centrifugal pump with low noise and paper core filter to speed-up oil supply, discharge and flush.

11) Equipped with the external fuel tank to increase the fuel tank design to ensure volume of oil pump; four groups of fuel pipes for injection to ensure a more stable function of processing and reduce the possibility of fire accident.

12) CNC transmission system consists of a Panasonic AC servo motor, PMI precision ball screw bar and precision linear guide to ensure accurate positioning.

13) The advanced functional components and precision assembly processing could ensure the movement accuracy of the machine.

14) The automatic lubrication oil path of system to add lubricant for each guide rail, screw bar, to effectively ensure the normal operation of the machine with high accuracy and improve the service life of the machine.

Control Systems and Software

1) Six CNC axis for perfect grinding

2) Upgraded drive technology to ensure a strong power and shorten the processing time.

3) Equipped with electronic hand wheel simple and convenient in operation which makes the machine quickly into the working station

4) The adaptive-adjustment of the empty running speed and the processing speed reduce the non-production time and ensure a shortest processing time

5) Forward and backward in a fast speed to ensure an accurate and reliable positioning

6) Realize a key turning, replace the new electrode wheel when the operation is convenient

7) Increase linkage function, shorten processing time, optimize processing process action, such as turning process

8) Added V1, V2 separate processing and single-axis switching processing functions

9) The humanized design with simply icon and filling- in type to ensure a more convenient and quick operation

10) Pulse power supply parameters can be stored in real time, convenient for the next processing of the same specification saw blade directly call

11) Simple in operation.It is required to input data in the operation panel to complete programming.

12) Real-time fault alarm

13) Save/restore function for the processing power, easy to use

Application

1) Rich processing expert database and mature processing strategy. The rich Apex tooth shape library has the expansion ability, simple in grinding and reduces the operation difficulty to the utmost, together with the side edge processing ability.

2) The automatic electrode function during the machine processing, and automatic compensation after the turning is completed thus to avoid non-accuracy of the machine processing due to the electrode loss.

3) The CNC gear shifting technology to reduce the non-processing time significantly and improve the degree of accuracy

4) The tooth processing in a cycle could be interrupted

5) Once fitting and once forming

6) The construction of the saw blade production line is lower in cost

7) To take use of the copper electrode wheel for cost-saving

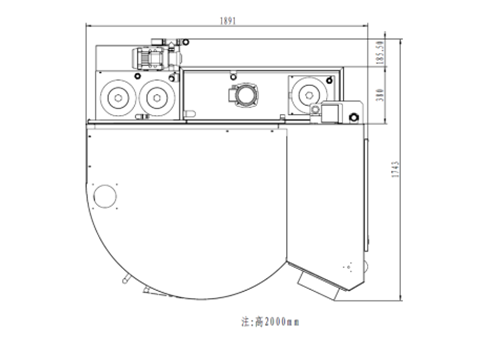

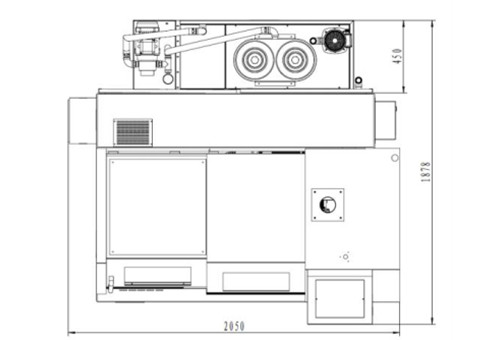

8) The processing depth could be settled due to requirements. The electrode wheel could automatically adjust the speed and steering according to the requirements. Machine Layout Map The following refer to the minimum size, it is suggested to leave operation distance: front (1000mm) back (700mm) left (500mm) right (500mm)

Environment Requirements

1)It is required to ensure ground wire reliable grounding.

2) The connection requirements of the main power: MF823 requires a three phase and four line system power connected under 380 volt, with a value difference range of +10%~-5%, while the sudden voltage change is not allowed which could also not be a common power supply for other electrical equipments with high voltage, or the user shall prepare voltage regulator, otherwise the consequences will be vain. In addition, it is required to take protection measures such as installing the air switches on the front of main power for the machine.

3) Connection requirements for gas path: the gas path of the MF823 machine requires inlet pressured dry and clean air of 0.5~0.8MPa.

4) Air must be clean without dust. There is no quake source near the machine. If any, it is required to install the machine on the foundation with anti-earthquake ditch.There is no dust source such as and grinding machine to ensure the air out of grinding particles.There is no chemical corrosive element indoor (far off the chemical lab, surface heating treatment workshop and etc). It is required to avoid higher humidity (with relative humidity among 40~60%) .

—Inside temperature Conditions: Guaranteed precision 20±3℃ Guaranteed Working 15~30℃

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

CMP (Chemical Mechanical Polishing) technology for CVD diamond enables ultra-smooth surfaces with nanometer-level roughness. By combining mechanical abrasion with chemical reactions, CMP delivers superior flatness, high precision, and damage-free polishing.

Learn how a customer optimized the grinding process for PCD scissors using vitrified and resin bond grinding wheels. This case highlights efficiency improvements and multi-material grinding solutions for textile machinery parts. Discover practical solutions to enhance grinding speeds and results with advanced wheel choices.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088