Grinding

Home / Grinding / PCD Grinding Wheel > Tungsten copper grinding wheel for EDM

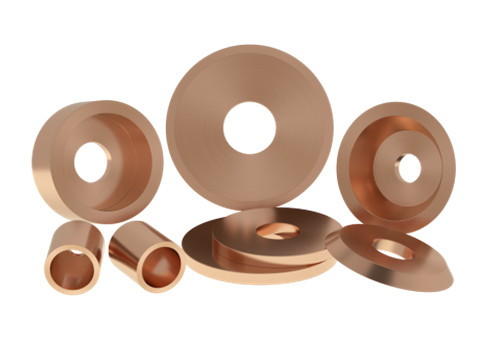

Copper Tungsten Erosion Wheels

Tungsten copper grinding wheel electrode for PCD EDM machining

perfectly meet the demands of Vollmer, Walter, Lach, Enokida, and Anca

CE type: equivalent size 6A2 ,1A1,1V1,11V9, 12V9,13VF8 etc.

Support customization and OEM

Tungsten copper grinding wheel electrode

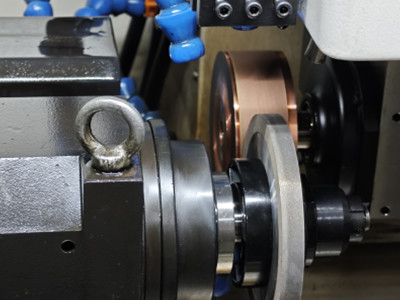

Tungsten copper electrodes are mainly used for electrospark machining (EDM) PCD tools, namely disc EDM (Disc Erosion Machining). This process is different from traditional mechanical grinding. Instead, it uses electric spark discharge to erode PCD materials layer by layer to achieve the purpose of precision machining tools.

Copper Tungsten Electrode (Cu-W) is a composite electrode made of highly conductive copper (Cu) and highly wear-resistant tungsten (W). It combines the high melting point and wear resistance of tungsten with the excellent conductivity of copper, making it an indispensable consumable when processing polycrystalline diamond (PCD) tools.

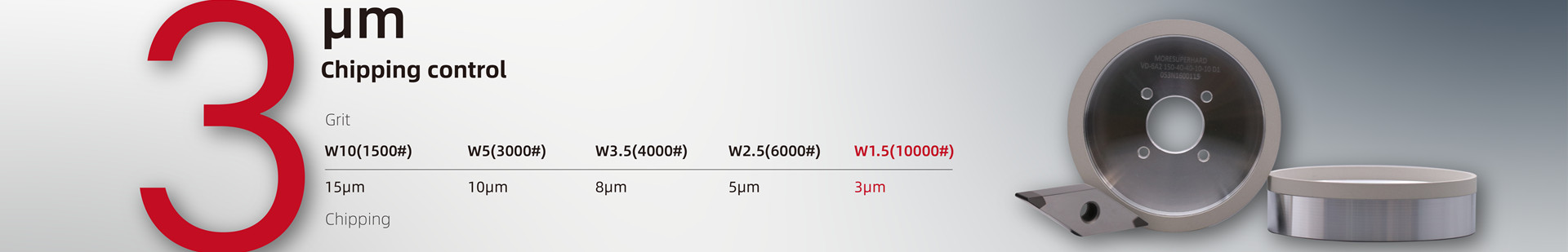

Features of tungsten copper erosion wheel electrodes

High wear resistance: Tungsten increases electrode life, reduces wear and improves processing stability.

Excellent conductivity: Copper ensures uniform discharge and improves processing accuracy.

Low thermal expansion coefficient: The electrode has good dimensional stability, ensuring processing accuracy and consistency.

Suitable for high-precision processing: Especially suitable for PCD tool edge processing, which can obtain sharp and uniform cutting edges.

Applications of PCD Eletrode

PCD end mills (right angle and rounded corners), PCD twist drills, PCD countersink drills, PCD reamer, PCD countersink reamer, PCD step tool, PCD woodworking tool (mixed slot tool), PCD profile cutting tools

Adaptable to EDM machining grinder

| Manufacturer | Country | Models |

| Vollmer | Germany | QXD 250, QM ECO SELECT, VHybrid 260, VLaser 370 |

| Walter (United Grinding Group) | Germany | elitronic Diamond Evolution, Helitronic Power Diamond |

| Anca | Australia | EDG3, EDG5 |

| Makino | Japan | EDAF, EDGE3 |

| EWAG (United Grinding Group) | Switzerland | Laser Line Ultra, Laser Line Precision |

| Lach Diamond | Germany | Dia-2200-mini, Dia-2100-classic |

Tungsten copper grinding wheel electrode grade

| Materials | Copper content |

Density(g/cm³)

|

Hardness(HB kgf/mm3) | Conductivity(%IACS) |

| 70Wcu | 30±2.0 | 13.8 | 175 | 42 |

| 75Wcu | 25±2.0 | 14.5 | 195 | 38 |

| 80Wcu | 20±2.0 | 15.15 | 220 | 34 |

Specifications of thngsten carbide grinding wheel electrode

| Products | Diameter | Hole sizes | Thickness |

| Cup type tungsten copper grinding wheel | 125 | 60 | 40 |

| Plated type tngsten copper griding wheel | 200 | 60 | 5 |

| Plated type tngsten copper griding wheel | 150 | 60 | 10 |

| Plated type tngsten copper griding wheel | 150 | 60 | 5 |

| Plated type tngsten copper griding wheel | 150 | 60 | 4 |

| Plated type tngsten copper griding wheel | 150 | 20 | 10 |

| Plated type tngsten copper griding wheel | 80 | 10 | 5 |

| Plated type tngsten copper griding wheel | 80 | 10 | 10 |

| Plated type tngsten copper griding wheel | 50 | 10 | 10 |

| Other specifications and sizes can be customized | |||

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088