Vitrified diamond grinding wheel sharpen pcd wood working tools grinding test

Rough grinding: 6A2 D150* H40 *T40*W20*X8

Fine grinding: 6A2 D150*H40*T40*W5*X8

Workpiece:PCD wood working tools

Grinding machine: ZT- 180

Comparison of vitrified diamond grinding wheel

D20 800#

| MORESUPERHARD | COMPRTITOR | |

| Grinding wheel size | 6A2, D150H40*T40*W20*X8 | 6A2, D150H40*T40*W20*X8 |

| Grinding wheel grain size | 800# (D20) | 800# (D20) |

| Machine | ZT-180 | ZT-180 |

| Workpiece | woodworking tools | woodworking tools |

| Material | PCD | PCD |

| Cutting edge | 4edges | 4edges |

| Working allowance |

0. 50mm / edge

|

0. 50mm / edge

|

| Amount of feed | 0.02mm | 0.02mm |

| Cutting speed | 16m/s | 16m/s |

| Oscillation | 20mm | 20mm |

| Result | ||

| Chipping | 0.021mm | 0.026mm |

| Grinding time | 10min | 11min |

| Life | 40 | 30 |

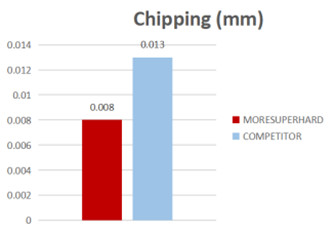

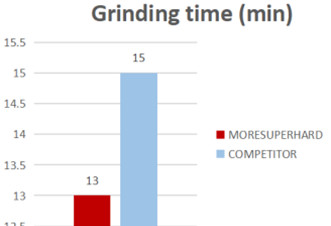

Comparison of vitrified diamond grinding wheel

3000# D5

| MORESUPERHARD | COMPRTITOR | |

| Grinding wheel size | 6A2, D150H40*T40*W5*X8 | 6A2, D150H40*T40*W5*X8 |

| Grinding wheel grain size | 3000# (D5) | 3000# (D5) |

| Machine | ZT-180 | ZT-180 |

| Workpiece | woodworking tools | woodworking tools |

| Material | PCD | PCD |

| Cutting edge | 4edges | 4edges |

| Working allowance |

0. 007mm-0.01mm / edge

|

0. 007mm-0.01mm / edge

|

| Amount of feed | 0.005mm | 0.005mm |

| Cutting speed | 16m/s | 16m/s |

| Oscillation | 20mm | 20mm |

| Result | ||

| Chipping | 0.008mm | 0.013mm |

| Grinding time | 13min | 15min |

| Life | 105 | 100 |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088