What is TPS diamond?

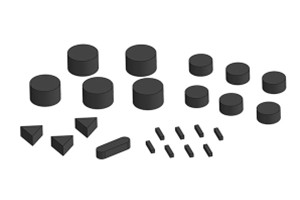

Thermally stable polycrystalline diamond is a polycrystalline diamond artificially synthesized with diamond single crystal micropowder under high temperature and high pressure. A special process is used to remove cobalt and other metal catalysts in polycrystalline diamond, eliminating the problem caused by the difference between metal impurities and the thermal expansion coefficient of diamond. The thermal cracking damage of polycrystalline diamond at high temperatures improves the thermal stability of polycrystalline diamond, with a heat-resistant temperature of over 1150°, allowing it to withstand the high temperatures required to manufacture drill bits using powder metallurgy processes. TSP particles have various shapes such as cylindrical and triangular shapes, and their particle size has reached a diameter of more than 25.4 mm, which is much larger than natural diamond.

The characteristic of thermally stable polycrystalline

1.TSP polycrystalline diamond has high wear resistance, high thermal stability and uniform structure.

2.TSP diamond has a very high wear ratio, the wear ratio can reach 30,000 to 100,000

3.Very low cost than natural diamond and pcd diamond,competitive prices

4.Shape and Sizes all can be customized freely.

Applications of TSP diamond

TSP diamonds are widely used in petroleum geological drill bits and diamond processing industries.

The performance of TSP drill bits is basically the same as that of surface-mounted natural diamond drill bits. Because its particles are larger than natural diamonds, its mechanical drilling speed is higher than that of natural diamond drill bits. When natural diamond resources are exhausted, TSP drill bits have become an extremely hard rock drill bit.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088