Advantages of Single Crystal Diamond Tools

With the advent of modern integrated technology, machining is developing in the direction of high precision, which places very high requirements on tool performance. Due to the small friction coefficient, low thermal expansion coefficient and high thermal conductivity of single crystal diamond, it can cut extremely thin chips. The chips flow out easily. It has low affinity with other substances and is not easy to produce built-up edge. It generates little heat and has high thermal conductivity. It can Avoid the impact of heat on the blade and workpiece, so the blade is not easily dulled, the cutting deformation is small, and a higher quality surface can be obtained.

Customer CVD diamond tools grinding case

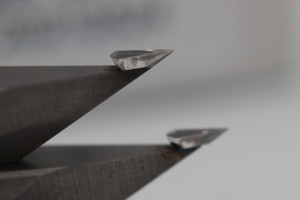

Workpieces :Inner concave MCD/CVD cutting tools

Grinding Requirement:Chipping control under 5μm

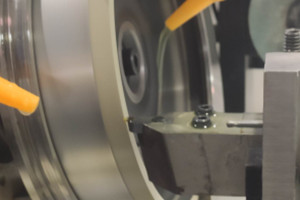

Grinding machine:Anca cnc grinding machine

Customer try to use resin bond diamond grinding wheel for grinding CVD single crystal diamond tools,But there are two problems that need to be solved.

1.Chipping control:The chipping is not up to standard and cannot be controlled within 5μm.

2.Low grinding efficiency:The grinding wheel is consumed too quickly, but the amount of workpiece removal is not obvious.

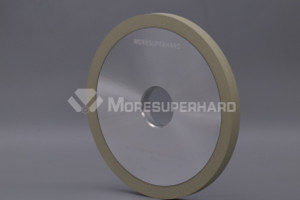

Moresuperhard has rich experience in grinding CVD/MCD diamond cutting tools.Usually,vitrified bond diamond grinding wheels are more suitable for grinding single crystal diamond cutting tools and moresuperhard' fine grain sizes ceramic diamond grinding wheel has good performance in grinding diamond tools.

According to the customer's grinder, Moresuperhard customizes a 1A1 parallel ceramic diamond grinding wheel for testing.Let’s look forward to a successful test result.

Comparison of the grinding effects of single crystal diamond tools with different particle size ceramic diamond grinding wheels in Moresuperhard

| Grain Sizes | Chipping |

| W20 | 30μm-35μm |

| W10 | 15μm-20μm |

| W5 | 5μm-7μm |

| W1.5 | 3μm-5μm |

This is a grinding experiment data,the specific grinding results need to be determined according to the grinding machine and grinding parameter settings.

<< :Applications of diamonds with different crystal structures

<< :The future of indexable inserts and peripheral grinding wheels

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088