Cylinder Head

The design of the cylinder head is the key to reducing fuel emissions and meeting stringent government regulations. Therefore, such parts have very high requirements for machining quality, involving very complex and demanding machining operations and non-standard tools.

The challenges you face in the manufacturing process:

• High efficiency and high surface finish

• Prevent chips from falling into the water channel of the part

• The pipe hole and valve seat are required to have high processing accuracy, stable dimensions and a good life

• Machining high-precision continuous surfaces with high roughness requirements

Close-tooth face milling cutter

High efficiency and high surface finish

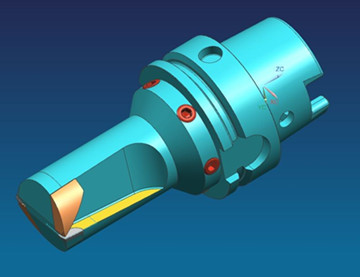

Back chip removal tool

Prevent chips from falling into the part waterway

On the cylinder head, some through holes are connected to the water channel. When processing with general tools, the chips will fall into the water channel due to poor control of the chip removal direction and affect the performance of the parts. Moresuperhard adds a chip guard to this tool, so as to control the chip to flow back without falling.

Non-standard reamer

It is required that the processing precision of the conduit hole and valve seat is high, Dimensionally stable and can have a better life

The non-standard reamer integrates HSK tool holders and combines multiple processing. The catheter hole reamer can be single-edged or multi-edged, made of cemented carbide or PCD. The catheter reamer uses a tapered connection structure to achieve rapid replacement. When processing the valve seat, an adjustable tool holder is used for maximum safety. Optional 4-blade or 8-blade full-face CBN blades can be combined to finish the different chamfers on the valve seat, which can ensure that the seat surface runout can reach more than 0.03.

Injector hole reamer

Process high-precision continuous surfaces with high roughness requirements

The injection nozzle holes have multiple sizes and continuous chamfered planes. At the same time, the holes have high precision and strict tolerances for each other. For this reason, we use a PCD precision reamer to complete all dimensions at one time. When processing different chamfering planes, different feed speeds can be used to ensure its cutting effectiveness, to ensure a smooth surface and qualified accuracy.

Case1:

Tool: Non-standard PCD nozzle hole reamer

Cutting parameters:

vc: 150 m/min

fz: 0.08 mm

ap: 0.2 mm

z: 2

Tool life: 1500 pieces

Case2:

Tool: Non-standard catheter valve seat reamer

Blade: PCD fine reamer, P8350, CBN200 blade

Cutting parameters:

Catheter:

Vc=80m/min, fz=0.08mm, ap=0.2mm, z=1

Valve seat:

Vc=100m/min, fz=0.1mm, ap=0.2mm, z=2

Tool life: 800 pieces of conduit, 250 pieces/blade of valve sea

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088