Brazing

Home / Brazing / PCD Brazing Machine > high speed vacuum brazing machine

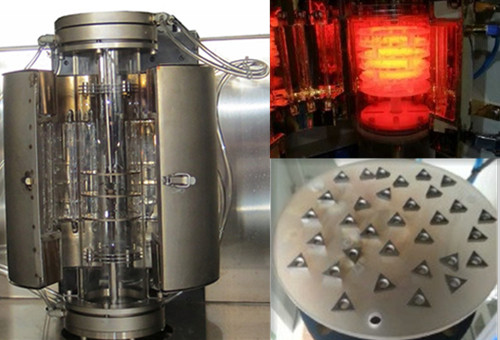

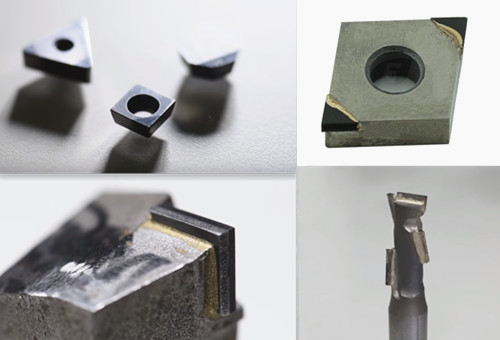

vacuum brazing machine is excellent for welding between superhard materials, tungsten carbide, ceramics and all kinds of diamond.The materials include ND (natural diamond),Synthetic Mono crystal diamond,CVD diamond,PCD/PCBN and cermet,etc.

vacuum brazing is often conducted in a vacuum chamber, this means that several joints can be made at once because the whole workpiece reaches the brazing temperature. vacuum brazing method realizes a shorter construction period, work environment improvement, enhancement of strength due to degassing and reduction of distortion due to wholly heating. The advantages include:

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

The finer the grinding wheel particle size, the smaller the cutting edge chipping, and the lower the grinding efficiency. For this reason, the PCD cutting tool sharpening process can be divided into three processing stages: coarse, fine, and fine according to the accuracy of the cutting edge of the tool, its purpose (see Table 1) or its failure degree (see Table 2). Formulating a reasonable sharpening process according to specific conditions can greatly improve processing efficiency.

MORESUPERHARD can not only provide you with efficient double surface fine grinding solutions, but also provide you with dressing solutions matching your double side grinding machine !

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088