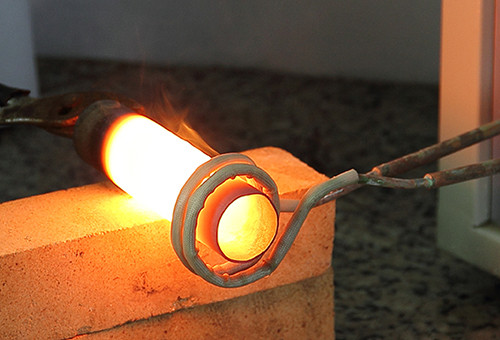

High frequency induction welding machine is used for welding pcd and pcbn inserts, carbide tool, diamond saw blade, and heating of small metal parts.

The high frequency induction brazing machine has advantages of induction heating speed, high efficiency, energy saving and low cost, the small oxidation area and the full solid welding, etc

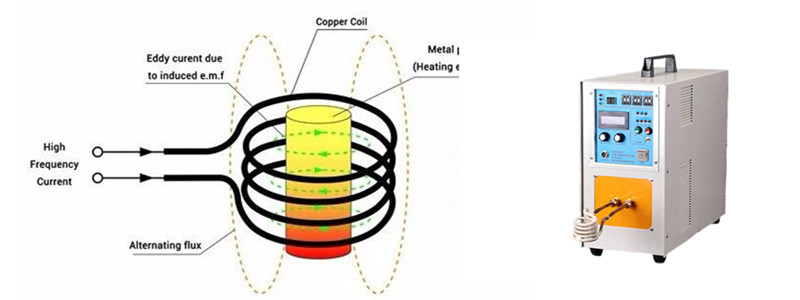

Working principle diagram of high frequency induction welding machine

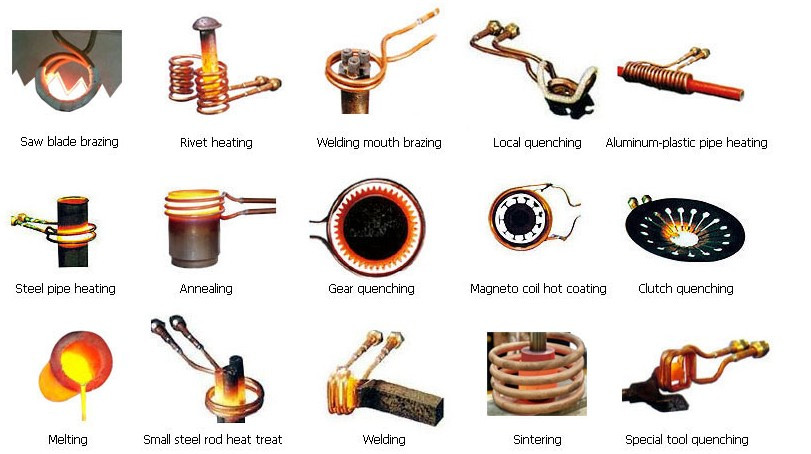

Applications of High Frequency Induction Brazing Machine

- Diamond PCD and PCBN tools, diamond saw blade brazing, sawtooth welding

- Brazing/welding of carbide tool ( such as turning tool, milling cutter, drill hot rolling, pliers, hammer, wrench, cutting pliers, etc)

- Composite brazing/ welding of metal materials. Heat treatment of auto and motorcycle parts, hot piers of standard parts, nut hot piers, copper standard heating

- Glass steel alloys frame brazing, small bearings quenching, annealing etc.

- Jewelries brazing, watchcase annealing and clock outer quenching.

- Electronics products brazing/welding/heating

- Precise mechanical parts brazing/heating.

- Stainless steel strip annealing etc.

- Melting of gold, silver, copper, brass of little amount

Technical Parameters of High Frequency Induction Welding Machine

|

Input Voltage |

Single phase 220v 50-60HZ ,

Three-phase 380V /50HZ |

|

Output oscillatory power |

3- 35kw |

|

Oscillation frequency |

30-50Khz |

|

Current input |

2-60A |

|

Duty cycle |

100% 40° |

|

Type

|

WH-VI-16 |

|

Input powder |

16KW |

|

Input voltage |

One phase 220V;50-60Hz |

|

Oscillation frequency |

30-50KHz |

|

Cooling water pressure |

≥0.03MPa |

|

Weight |

24kg |

|

Dimensions |

225×480×450mm |

|

Type

|

WH-VI-26 |

|

Input powder |

26KW |

|

Input voltage |

Three phase 380V;50-60Hz |

|

Oscillation frequency |

30-50KHz |

|

Cooling water pressure |

≥0.05MPa |

|

Weight |

60kg |

|

Dimensions |

265×600×540mm |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088