Efficient heat dissipation: Provides higher thermal conductivity than traditional heat dissipation materials such as copper and aluminum.

Performance improvement: Combines high thermal conductivity and electrical insulation to improve the performance and efficiency of electronic devices.

Maximum Diameter:70mm

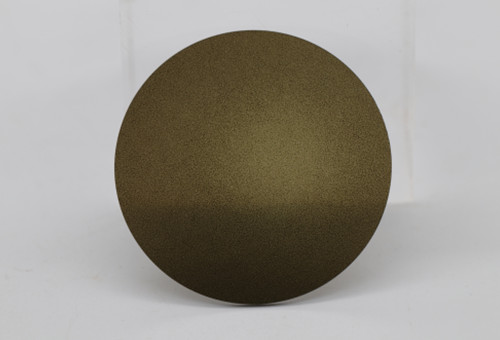

Polycrystalline CVD diamond heat sink materials

CVD (Chemical Vapor Deposition) polycrystalline diamond is a diamond material made by vapor deposition and contains multiple grains. Unlike single crystal diamond, polycrystalline diamond is composed of many small grains forming a polycrystalline body. This material has excellent thermal conductivity, high hardness and wear resistance, making it ideal for efficient heat dissipation applications in electronic and optoelectronic devices.

Features of polycrystalline CVD diamond heat sink materials

High thermal conductivity: The thermal conductivity of polycrystalline diamond typically ranges from 1000 to 1500 W/m·K, which, while slightly lower than single-crystal diamond, is still significantly higher than traditional heat sink materials such as copper and aluminum.

Chemical stability: Polycrystalline diamond is highly resistant to most chemical agents, making it suitable for applications in harsh environments.

Electrical insulation: It is an excellent electrical insulator, preventing electrical shorts and electrical interference.

Polycrystalline CVD diamond details

| Maximum diameter(mm) | Thickness | Minimum roughness | Thermal conductivity |

| 70mm | 0.3mm-3mm | 10nm | 800-1500W(m.K) |

Applications of CVD polycrystalline diamond plate

High-power electronics: Used as heat sinks in high-power semiconductor devices (e.g., power amplifiers, power transistors) to ensure efficient heat dissipation.

LEDs: Help high-brightness light-emitting diodes manage heat, extend their life and improve performance.

Microwave and RF devices: Ensure stable operation of microwave and RF electronics under high heat loads.

Laser diodes and optoelectronic devices: Used in laser systems and high-performance photodetectors for thermal management and improved device efficiency.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088