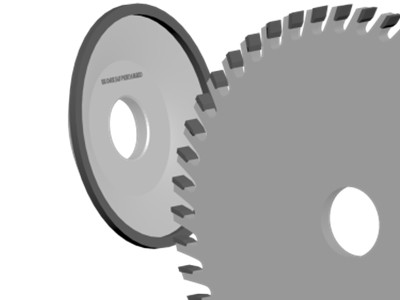

PCD (Polycrystalline Diamond) woodworking tools are widely used in wood processing for their exceptional wear resistance and high cutting efficiency. However, as these tools are used, their sharpness gradually diminishes, resulting in a decline in processing quality and efficiency. Timely resharpening of PCD woodworking tools is key to maintaining their superior performance. This article explores the importance of resharpening PCD woodworking tools, the problems that arise from improper resharpening, and why ceramic diamond grinding wheels are the best choice for sharpening PCD woodworking tools.

PCD tools are typically used in high-precision and high-speed cutting tasks. Particularly in wood processing, these tools are subject to significant cutting forces due to their high hardness. Over time, however, the tool edges begin to dull. If the tools are not resharpened in a timely manner, it will negatively impact processing results.

If PCD woodworking tools are not resharpened properly, several issues may arise:

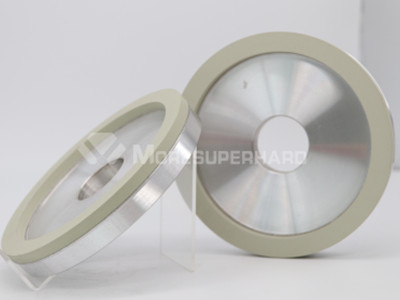

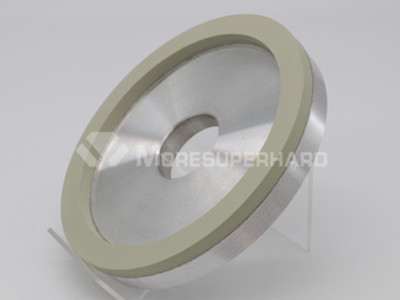

Choosing the right grinding wheel is crucial when resharpening PCD woodworking tools. Ceramic diamond grinding wheels, when compared to resin bond diamond wheels, offer several distinct advantages, making them the ideal choice for resharpening PCD woodworking tools:

After discussing with the customer, we decided that using 400# and 800# grain size ceramic diamond grinding wheels for resharpening PCD woodworking tools would be the best choice. Here's why:

By using these two grain sizes in combination, PCD woodworking tools can be restored to optimal cutting conditions, preventing tool chipping and surface marks and meeting customer requirements for precise and smooth wood processing.

Resharpening PCD woodworking tools is crucial for maintaining cutting quality, extending tool life, and ensuring efficient production. Improper resharpening can lead to tool chipping, surface marks on the wood, and decreased processing efficiency. Ceramic diamond grinding wheels, particularly those with 400# and 800# grain sizes, provide superior grinding performance, increased precision, and longer durability compared to resin bond wheels. Choosing ceramic diamond wheels for resharpening PCD woodworking tools ensures a sharper tool edge, better surface quality, and improved overall processing results, making it the best choice for efficient and precise woodworking.

<< :Customer Case: Optimization of PCD Scissors Grinding

<< :High-Efficiency Grinding of PDC Cutters with Ceramic Diamond Grinding Wheels

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088