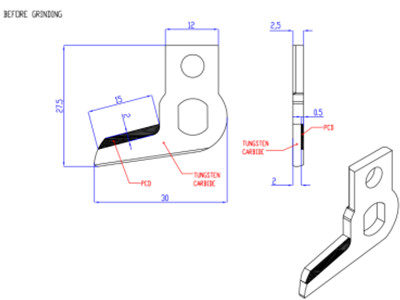

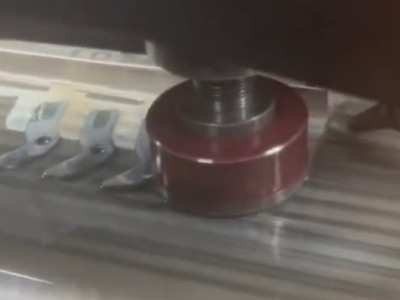

The customer uses a Ziersch & Baltrusc surface grinding machine to process PCD scissors for textile machinery used to cut short threads. The customer has been facing issues with slow grinding speeds and low grinding efficiency.

The specific processing conditions are:

The customer was concerned whether the equipment was outdated or unsuitable for processing this type of material. After analysis, it was determined that the equipment does not need replacement; the problem lies in the required precision for processing the flat surfaces, which puts heavy demands on the machine.

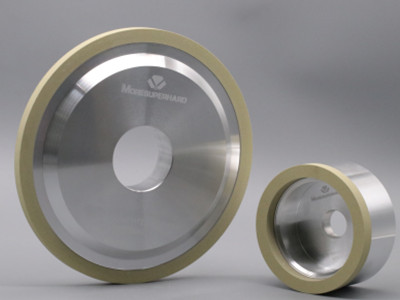

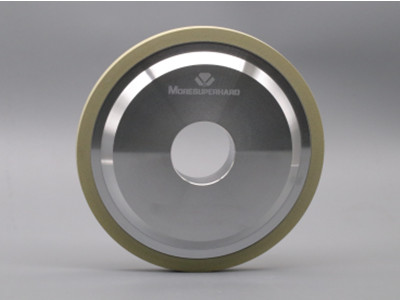

To improve grinding efficiency and solve the issue of unsatisfactory grinding results, the following measures were recommended:

While the dull appearance of the carbide surface isn't a major issue, improving surface brightness could be desirable. If possible, choosing the right grain size and bond type can improve the finish, achieving a more polished result.

By adjusting the grinding wheels and processes, grinding efficiency for PCD scissors can be greatly improved without the need for equipment replacement. The customer can now achieve better results by using coarser vitrified bond wheels and resin bond wheels for specific materials. This optimized solution serves as a valuable reference for grinding multi-material workpieces, especially when dealing with complex material combinations.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Learn about wire drawing dies, essential tools in metal wire processing used to reduce wire diameters and improve surface quality. Discover the different types of dies (tungsten carbide, PCD, natural diamond, and CVD diamond) for various metals and applications, including their material properties, functions, and selection guidelines. Understand how to choose the right die for precise wire drawing, enhancing efficiency, quality, and cost-effectiveness in industries like power transmission, semiconductor packaging, and medical device manufacturing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088