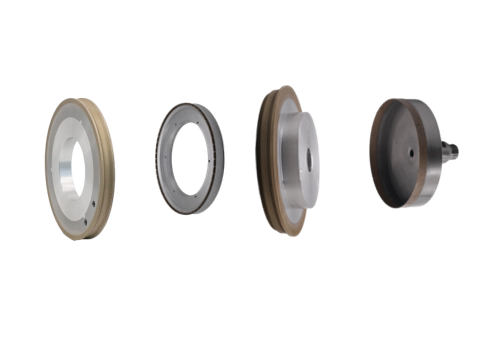

Applications:Dressing metal diamond and metal CBN grinding wheel

The minimum radius of curvature that can be machined is 0.1mm

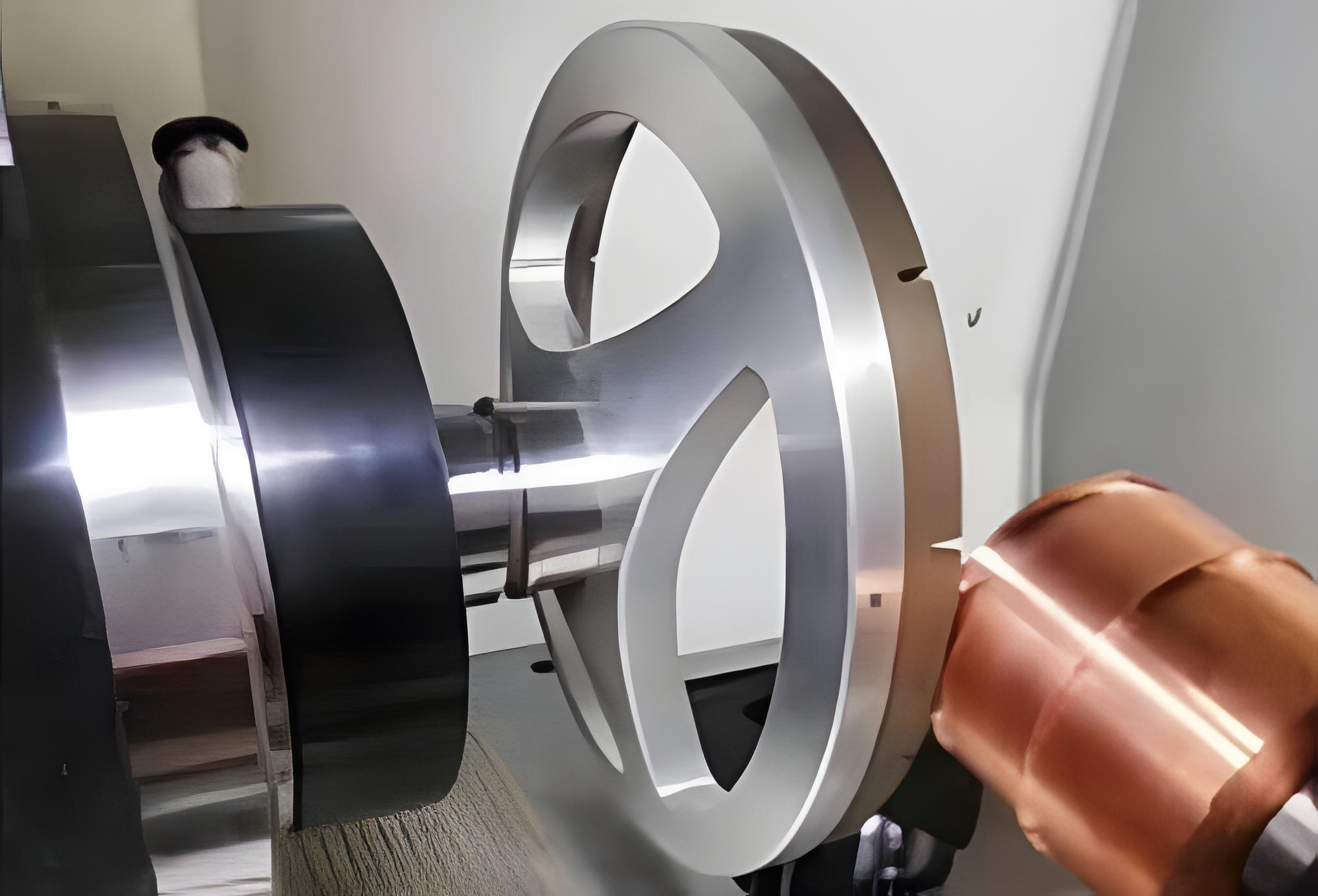

Online prototyping of CAD format graphics

Online electrode repair

Easy to operate

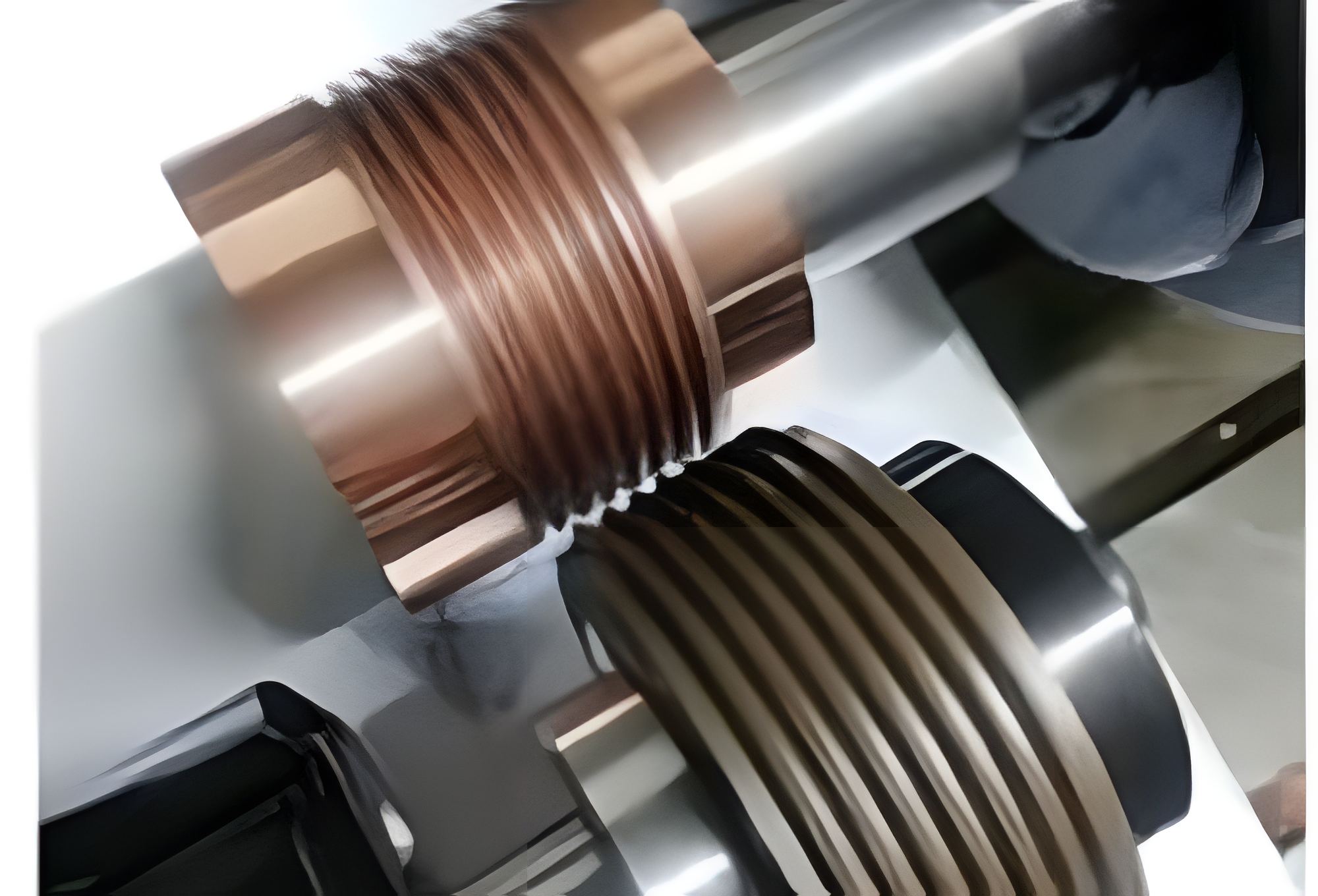

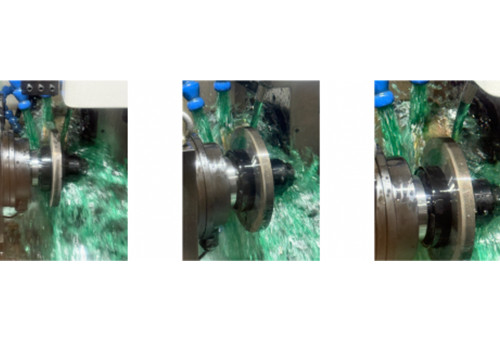

Diamond grinding wheels are made from diamond abrasive as raw material, using metal powder, resin powder, ceramics, and electroplated metal as binders to create products of various shapes. They are ideal grinding tools for hard and brittle materials such as cemented carbide, ceramics, and glass. Metal-bonded grinding wheels are widely used due to their high bonding strength, good formability, and long service life. Both metal-bonded diamond and CBN grinding wheels are processed by electrical discharge machining (EDM) dressing machines.

1.High-efficiency and precise processing

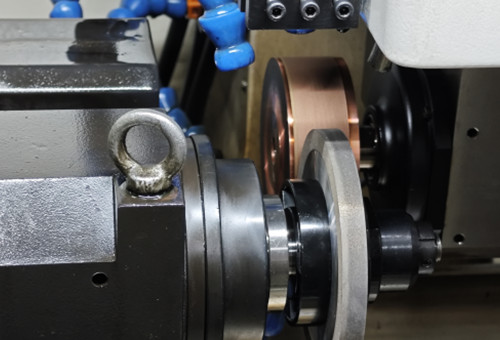

It can automatically process grinding wheels with a diameter of 300mm or less and a weight not exceeding 10KG, and is equipped with a dressing servo feed function. The minimum radius of the turning arc is 0.1mm. It has circumferential and radial servo modes, and the processing accuracy reaches ±0.02mm, meeting the high-precision requirements.

2.Advanced process guarantee

Equipped with a dedicated power supply to reduce diamond particle burns. It is equipped with online electrode repair and compensation functions to ensure that the electrode is always in the best condition and maintain a stable processing effect.

3.Convenient protection design

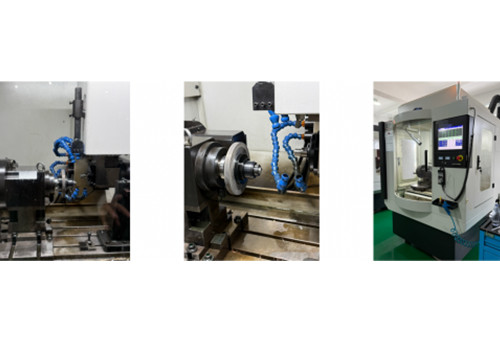

It adopts the standard interface of CNC machine tools, facilitating equipment connection. The machine tool is fully enclosed and protected to prevent the splashing of processing fluid, ensuring operational safety and a clean processing environment.

4.The machine tool adopts an integrated design and is specially designed for metal-bonded grinding wheels.

It is easy to install, leaving ample operating space for operators and significantly enhancing work convenience.

5.The high-precision characteristics of the electrical discharge machining special machine are remarkable: the workpiece and the electrode can rotate relatively, and the processing accuracy exceeds that of ordinary electrical discharge machining equipment.

6.The intelligent operation advantages of the dedicated electrical discharge machining machine are significant: it can automatically adjust the electrode according to the predicted wear and tear, can adjust the electrode online, support the online forming of CAD format graphics, and has high servo processing accuracy, comprehensively enhancing the intelligent operation level and processing efficiency.

●The processing objects are metal-bonded diamond grinding wheels and metal-bonded CBN grinding wheels.

●It is suitable for the production of grinding tools for hard and brittle materials such as cemented carbide, ceramics and glass.

●It can automatically complete shape processing based on design drawings, meeting various processing requirements.

| Machine sizes(mm)length*width*height | 220*1800*2300 |

| Machine Weight | 1100kg |

| Machine structure | Type"C"structure |

| System | |

| Control System | Industrial computer |

| Operation System | Windows 7 |

| Input mode | Toch screen ,in Chinese |

| Display mode | 15 inch LED |

| Drive mode | XYZ AC servo |

| Minimun drive unit | 1μm |

| Safety configuration | Automatic fire extinguisher,photosensitive probe |

| Machining parameter | |

| X,Y axis travel | 250*150mm |

| X,Y axis resolution ratio | 1μm |

| Rotatable angle of A-axis to the shaft center | 0°-360° |

| A-axis runout precision after installing rod | <0.01mm |

| Grinding diameter parameter | <300mm |

| Installation aperture | Φ20/Φ25.4/Φ30/Φ40/Φ60, customer made |

| On-line detection accuracy of tool machining | <0.02mm |

Moresuperhard also provide tungsten copper electrode dressing wheel,Welcome your inquire.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088