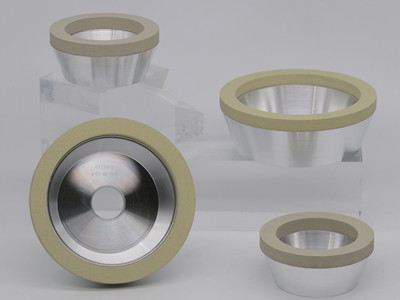

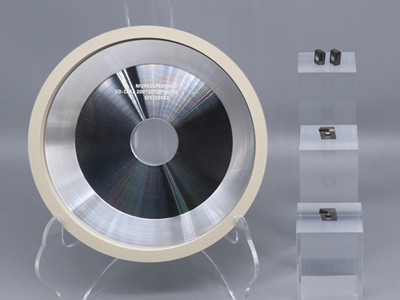

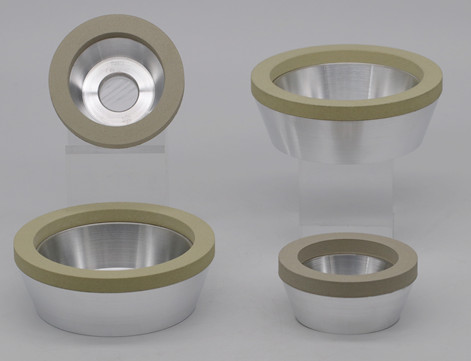

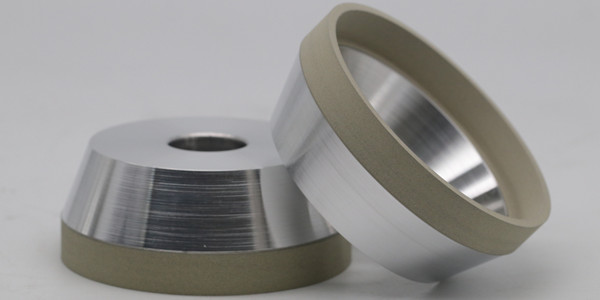

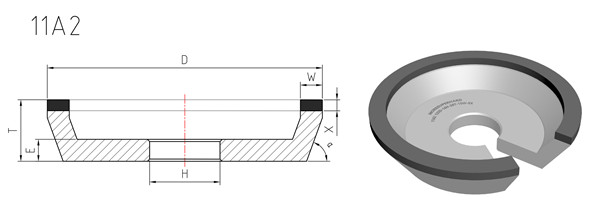

Type: 11A2 vitrified diamond wheel

Bonded: vitrified bond (ceramic)

Grit Size: W3.5, W5, W10, W20, W28, W40 (rough/ medium/finish)

Application: grinding pcd, pcbn tools, MCD and natural diamond tools

Diamond vitrified grinding wheels are designed for precision sharpening of cutting tools in the form of inserts and cutting tools made of polycrystalline PCD, polycrystalline PCBN, natural diamonds and a new type of engineering structural ceramics.

The vitrified diamond wheel has uniform micro porosity allow wheel to cut sharp and aggresive prevent the clogging the wheel's surface.

Application of vitrified diamond grinding wheel

Moresuperhard produce a wide range of diamond wheel in vitrified (ceramic ) bond for precision grinding, finishing, sharpening, peripheral grinding of PCD, PCBN, MCD and natural diamond.

- For PCD, PCBN super-hard cutting tools grinding

- For PCBN cutting tools grinding

- For polycrystalline diamond compacts ( PDC ) grinding

- For tungsten carbide cutting tool grinding

- For ceramic tools grinding

Specifications Of Vitrified (ceramic) Diamond Wheel

|

Type |

D(mm) |

T(mm) |

H(mm) |

W(mm) |

X(mm) |

|

11A2 |

100 |

40 |

32 40 |

3 5 10 20 |

10 |

|

125 |

40 |

32 40 |

3 5 10 |

10 |

|

|

150 |

40 |

32 40 |

3 5 10 15 20 |

10 |

|

|

Grit: 325/400 W40(500#) W28(600#) W20(800#) W10(1500#) W7(2000) W5(3000#) W3.5(4000#) 6000# |

|||||

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088