Vitrified Diamond Grinding Wheel For Cermet Rotary Tools

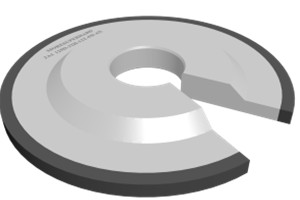

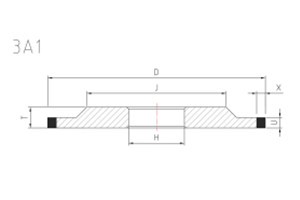

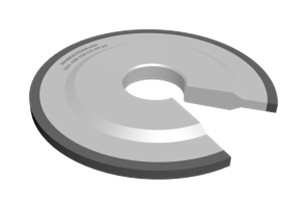

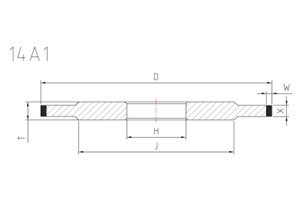

Mold:3A1,14A1

Bond:vitrified bond or ceramic bond

Applicatons:cylindrical grinding for cermet end mill,cermet drill ,ceramic reamsers

Characteristic:high grinding efficiency,good shape retention,porous structure,not easy to block,easy to dress

Basic characteristics of cermets

Cermet not only maintains the high strength, high hardness, wear resistance, high temperature resistance, oxidation resistance and chemical stability of ceramics, but also has good metal toughness and plasticity.

Advantages of Cermet Milling Cutters

1.Suitable for high-speed finishing of mild steel, carbon steel, alloy steel and stainless steel

2.Excellent chipping resistance and wear resistance, excellent thermal conductivity is the best choice for steel processing

3.Long tool life during high-speed finishing

Why choose vitrified diamon cylindrical diamond grinding wheel for grinding cermet rotary tools?

Cermet blades have both the hard and brittle characteristics of ceramics and the toughness of hard metals.Generally speaking, resin diamond is good at grinding hard and brittle materials, but hard and tough materials are easy to heat up when grinding, and resin is not heat-resistant, resulting in poor grinding efficiency and grinding wheel life. Therefor, vitrified bond should be selected Diamond grinding wheel, the heat resistance of ceramics, the grinding wheel has a long life, and can ensure that the diamond can be held in the case of a high edge.

Characteristcs of Moresuperhard cylindrical vitrified diamond grinding wheel

►Good self-sharpening, capable of high-efficiency cylindrical grinding.

►The roundness and cylindricity of the processed cermet end mill have high precision and good dimensional consistency.

►The surface finish of finely ground workpiece is good.

►Suitable for coarse grinding, semi-finishing and precision grinding.

Products Details:Specifications and Drawings

| Model | D(mm) | T(mm) | H(mm) | X(mm) | U(mm) |

|

3A1 &14A1 |

300 | 20 | 127 | 10 | 10 |

| 350 | 20 | 127 | 10 | 6 | |

| 400 | 35 | 152.4 | 10 | 7 | |

| Other specifications and models can be customized according to customer needs. | |||||

Suit different cylindrical grinding machine.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088