Grinding

Home / Grinding / PCD Grinding Wheel > Cylindrical Diamond Wheel for PCD Reamers

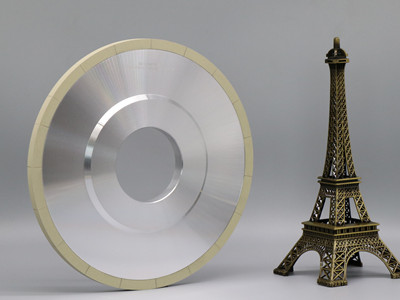

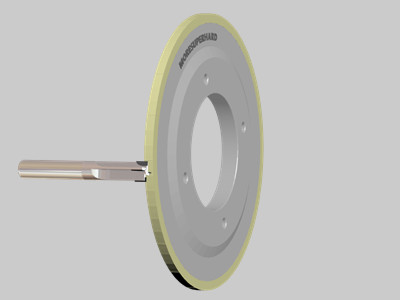

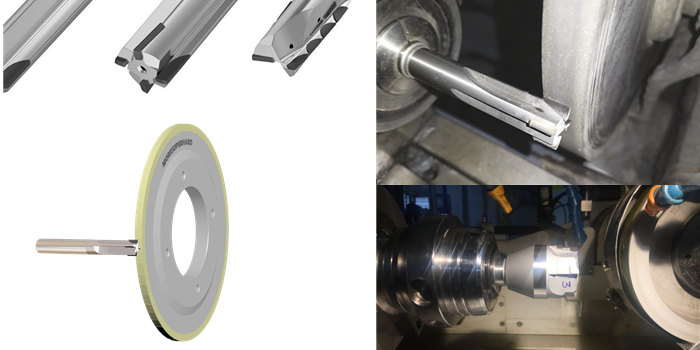

Application: cylindrical grinding PCD reamer

Bonded: vitrified bond or ceramic bond

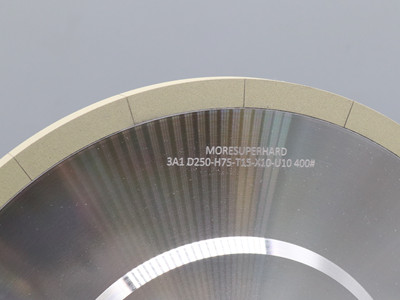

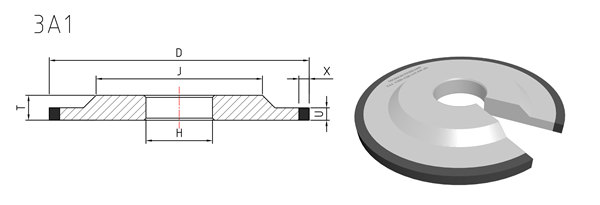

Model: 3A1, 14A1 grinding wheel

How do you grind a reamer?

MoreSuperhard vitrified cylindrical diamond wheel is used for grinding PCD reamer. It enjoys high grinding power, long working life and good surface quality.

Grinding PCD reamer with the OD of the vitrifed diamond wheel . You may want to experiment with the sharpening first , as this is the area you will be grinding off to make the pilot anyway . For a straight reamer it's often enough to grind the reamer to size. Grind a slight back taper (about .001 over an inch) to prevent the reamer from sticking. If the margin (circular lands) gets too large you can relieve the edge, leaving a margin about .004. If you reduce the diameter too much you may have to resharpen the chamfered cutting edges.

Applications of PCD reamers

- Cylindrical vitrified diamond grinding wheel is used for PCD tools grinding with large cylindrical grinding machines. The PCD tools in automotive industry include PCD profile cutters, PCD reamers and PCD milling cutters.

- Reamers are an effective option for hole finishing. Reaming with a PCD tool allows the user to ream holes faster, to tighter tolerances and produce cleaner-edge holes than is possible with carbide or HSS tooling.

- Aluminum engine blocks also require the truer holes that PCD reaming produces to achieve required performance levels. Aerospace and automotive manufacturing industries.

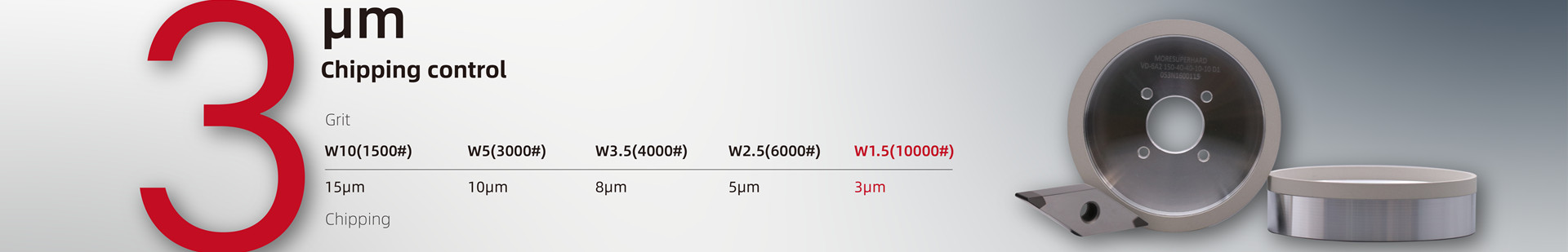

Specifications of cylindrical diamond grinding wheel

| Model | D(mm) | T(mm) | H(mm) | X(mm) | U(mm) |

|

3A1/ 14A1 |

300 | 20 | 127 | 10 | 10 |

| 350 | 20 | 127 | 10 | 6 | |

| 400 | 35 | 152.4 | 10 | 7 | |

|

Grit: 325/400, W40(500#), W28(600#), W20(800#) Other specifications can be made according to customers requirement. |

|||||

|

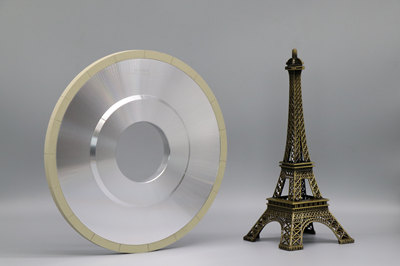

Specification: 14A1-D350-H127-X10-U6-T20 ,W20

Machine Name:Micromatic machine (Model: GCU X 260 X 500 / S)

Wheel RPM: 1500 rpm

Operation: Cylindrical Grinding

Coolant Type: Flushing Type

Dressing Tool: In house dresser wheel

Workpiece: PCD Reamer Work piece material: Poly Crystalline Diamond PCD

Work piece condition : Brazed Stock removal : 0.10 ~ 0.15 mm |

|

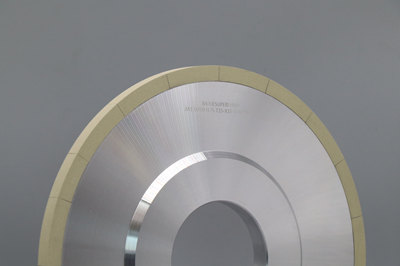

Advantages Of Cylindrical Vitrified Diamond Wheel

- Enjoys strong sharpness, high self-sharpening. Good surface finish after grinding.

- High efficiency, less dressing time, long service life and stable quality.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088