Diamond grinding wheel for PCD piston tools

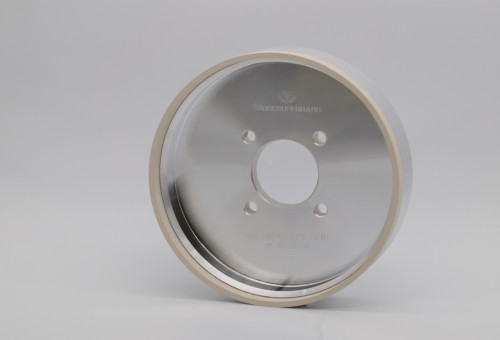

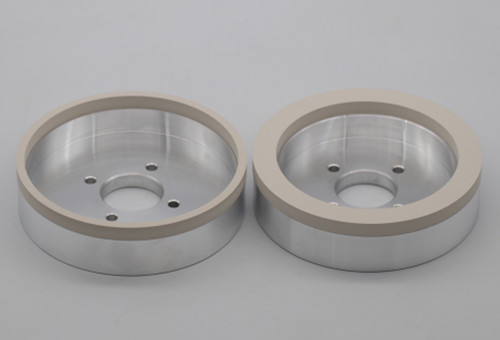

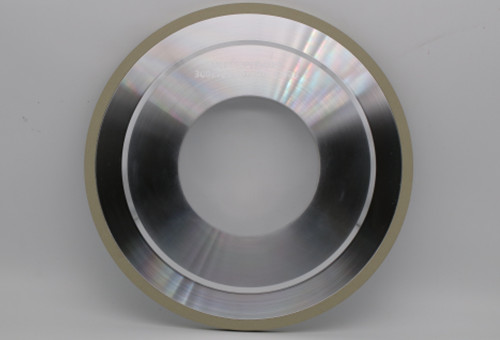

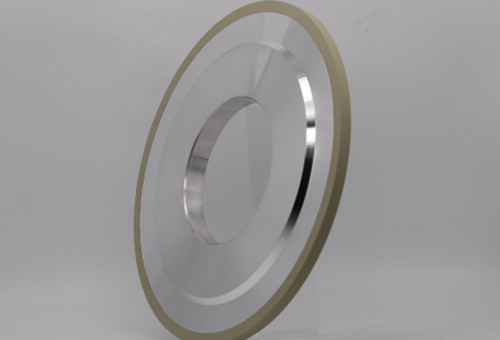

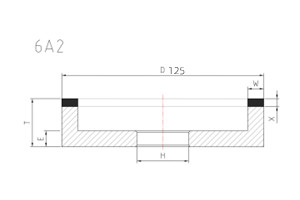

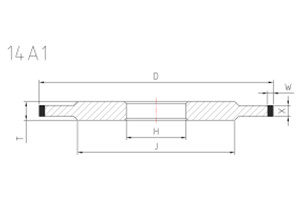

Mold:6A2,3A1,14A1

Bond:vitrified bond

Grain Sizes:W40,W20,W10,W5,W1.5 and other customized grain sizes

High efficient and long service life

Alumium Piston

The piston is one of the important parts of the engine, especially the aluminum piston, which has a series of advantages such as light weight, low thermal expansion coefficient, good thermal conductivity, corrosion resistance and wear resistance, etc. The main material of alumiun piston is aluminum-silicon alloy, of which The silicon content is more than 12%, and it is mostly used in automobile engines.

PCD Tools for alumium piston

PCD tools have always had advantages in processing aluminum, cast aluminum, aluminum alloy, etc., The processing life of PCD tools is several to dozens of times that of cemented carbide tools, so PCD tools have many advantages in cutting aluminum pistons. First, the hardness of PCD is relatively high wear-resistant and other advantages.secondly, the PCD tool is sharp and the cutting force is small, and the surface roughness of the machined surface can meet the technical requirements of the aluminum piston, improve the processing efficiency, and also reduce the cost. Therefore, PCD tools are widely used in the processing of aluminum pistons. , especially for batch processing manufacturers.

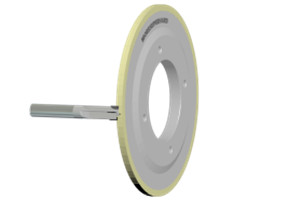

Moresuperhard provide diamond grinding wheel for grinding PCD piston tools including pcd turing tool,pcd grooving tools ,pcd reamers and pcd drills

6A2 vitrified diamond grinding wheels are commonly used for grinding PCD tools including PCD turning tools and pcd grooving tools.Suit most popular pcd grinding machine like Coborn Rg9,Coborn RG9A, Ewag.

Vitrified diamond cylindrical diamond grinding wheel for grinding PCD rotary tools including pcd reamers and pcd drills for alumiun piston.Moresuperhard provide 3A1,14A1,1A1 cylindrical diamond grinding wheel with custmized specifications and grain sizes.

Why choose vitrified diamond grinding wheel for grinding pcd piston tools?

1.The grinding efficiency of vitrified bond diamond grinding wheel is more than 3 times that of resin diamond grinding wheel when grinding pcd;

2.Vitrified diamond wheels require little dressing during the entire grinding PCD process

3.Large feed rates can be used for grinding PCD with a vitrified bonded vitrified diamond wheel

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088